Understanding-Muda-The-Waste-Elimination-Playbook - Level 1

Understanding Muda: The Waste Elimination Playbook – Level 1

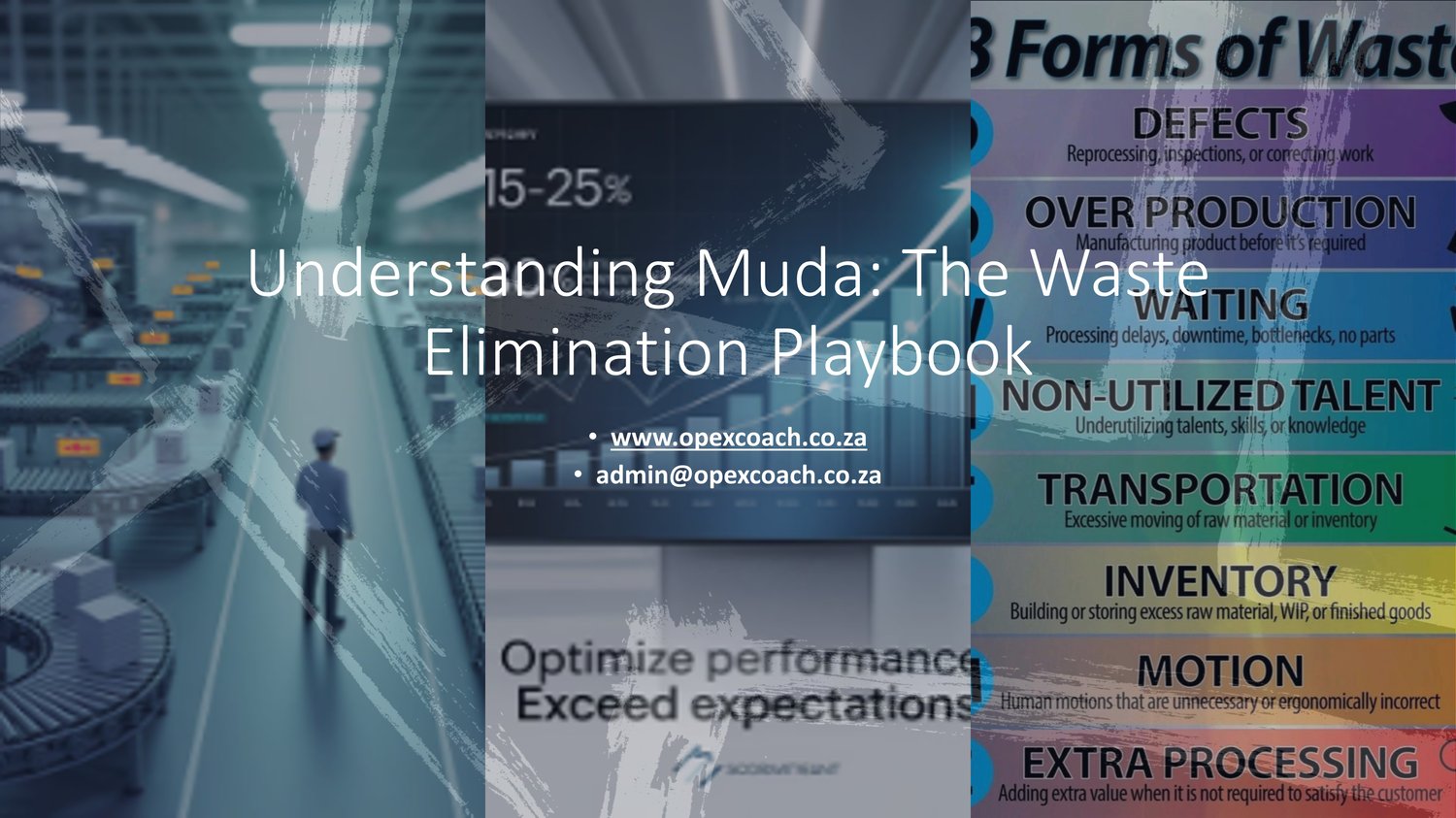

This presentation explains Muda—the Lean concept of waste—as a cornerstone of the Toyota Production System and operational excellence. Muda refers to non-value-adding activities, with two types:

- Type 1: Necessary but non-value-adding (e.g., compliance checks).

- Type 2: Pure waste, removable immediately.

Alongside Mura (unevenness) and Muri (overburden), Muda reduction can cut costs 15–30% and boost customer satisfaction. The framework addresses the seven wastes: each with industry examples, impact data, and real-world results (Toyota, Harley-Davidson, Caterpillar, Dell, P&G, Intel, Medtronic, etc.).

The playbook outlines a 5-phase roadmap:

Common pitfalls are addressed with structured mitigation strategies. Properly applied, this system can achieve >30% cycle time reduction, >12 annual inventory turns, and defect rates <1.7 per thousand, turning waste elimination into a sustained competitive advantage.