Three-dimensional machine vision, often referred to as 3D machine vision or 3D vision technology, is a cutting-edge field that has gained immense significance in recent years. This technology has the capability to capture and process three-dimensional information from the real world, enabling machines to perceive depth, shape, and size, similar to how humans do. In this article, we will delve into the fascinating world of 3D machine vision, exploring its applications, technological advancements, and the profound impact it is having on various industries. Amazon.com

Understanding 3D Machine Vision

- What is 3D Machine Vision?

3D machine vision involves the use of specialized cameras, sensors, and software to capture and analyze three-dimensional information about objects and scenes. Unlike traditional 2D vision systems, which can only provide flat representations of objects, 3D machine vision systems create a detailed spatial understanding of the environment.

The core components of a 3D machine vision system include:

- Cameras: High-resolution cameras capable of capturing depth information through various techniques such as stereo vision, time-of-flight (ToF), structured light, or LiDAR.

- Lighting: Appropriate lighting is crucial to illuminate the scene and create contrast for accurate depth perception.

- Processing Software: Advanced algorithms and software are used to process the captured data, construct 3D models, and extract relevant information.

- How Does it Work?

Different 3D machine vision technologies employ distinct methods for depth perception:

- Stereo Vision: This technique involves using two cameras with slightly offset viewpoints to create a disparity map, which is then used to calculate depth information based on triangulation.

- Time-of-Flight (ToF): ToF cameras emit short bursts of light and measure the time it takes for the light to bounce back from objects. By analyzing the time delay, ToF cameras can calculate the distance to objects.

- Structured Light: A projector emits a pattern of structured light onto the scene, and cameras capture how this pattern is deformed by the objects in the scene. The deformation is used to compute depth.

- LiDAR (Light Detection and Ranging): LiDAR sensors use lasers to send out pulses of light and measure the time it takes for the light to return after bouncing off objects. These measurements create a point cloud that represents the 3D environment.

Applications of 3D Machine Vision

The versatility and precision of 3D machine vision have led to its widespread adoption across various industries. Here are some key applications:

- Manufacturing:

In manufacturing, 3D machine vision is a game-changer. It enables quality control, ensuring that products meet strict dimensional and geometric tolerances. This technology is used for tasks such as:

- Inspection of manufactured parts for defects, ensuring they conform to design specifications.

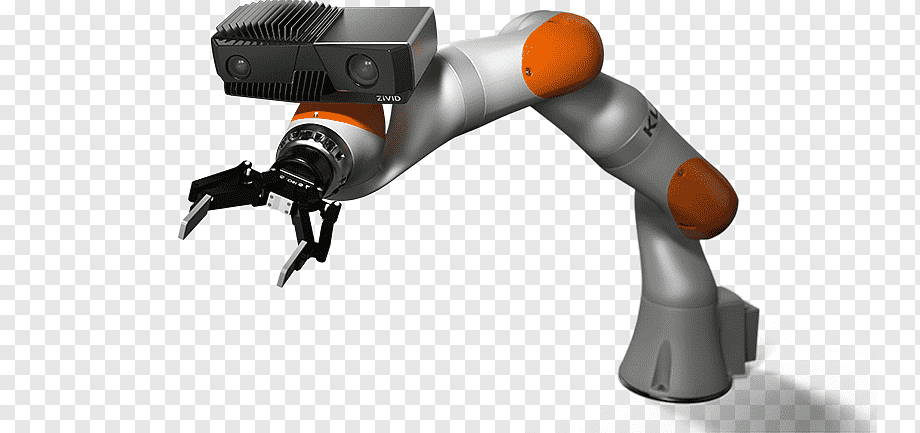

- Robot guidance and automation, allowing robots to pick and place objects accurately in dynamic environments.

- 3D printing, where 3D vision is used to monitor the printing process and ensure print quality.

- Healthcare:

The medical field benefits greatly from 3D machine vision. It is used in applications such as:

- Surgical navigation, assisting surgeons in performing precise procedures.

- Dentistry, for creating digital models of patients' teeth and designing custom dental appliances.

- Medical imaging, providing 3D reconstructions of the human body for diagnosis and treatment planning.

- Automotive:

In the automotive industry, 3D machine vision plays a critical role in enhancing safety and automation:

- Advanced driver-assistance systems (ADAS) rely on 3D vision for features like adaptive cruise control, lane-keeping assistance, and collision avoidance.

- Quality control in automotive manufacturing, ensuring that vehicle components meet strict standards.

- Autonomous vehicles use LiDAR and other 3D vision technologies to perceive their surroundings and navigate safely.

- Agriculture:

In agriculture, 3D machine vision is used to optimize farming processes:

- Precision agriculture techniques employ 3D vision to monitor crop health, detect pests, and manage irrigation.

- Autonomous farming equipment, such as robotic tractors, utilize 3D vision for navigation and operation.

- Retail and Logistics:

In the retail and logistics sectors, 3D machine vision enhances inventory management and customer experiences:

- Automated warehouses use 3D vision to optimize the storage and retrieval of goods.

- Augmented reality (AR) applications enable customers to visualize products in their own space before purchasing.

- Aerospace:

Aerospace engineering relies on 3D machine vision for:

- Quality control of aerospace components and structures.

- Robotic assembly and maintenance of aircraft.

- Guidance systems for drones and other unmanned aerial vehicles.

Technological Advancements in 3D Machine Vision

The rapid evolution of 3D machine vision technology has been driven by advancements in hardware and software. Some notable developments include:

- Improved Cameras:

Modern 3D vision systems benefit from high-resolution cameras with faster frame rates, enabling real-time data capture and analysis. Additionally, cameras with higher dynamic ranges and sensitivity to various wavelengths of light have expanded the technology's capabilities.

- Enhanced Algorithms:

The sophistication of 3D vision algorithms has grown significantly. Machine learning and deep learning techniques have been applied to improve object recognition, segmentation, and pose estimation. These advancements have made 3D vision systems more robust and adaptable to complex environments.

- Integration with AI and Robotics:

3D machine vision is increasingly integrated with artificial intelligence (AI) and robotics. AI-powered systems can make real-time decisions based on 3D data, enhancing automation and control in various applications.

- Miniaturization:

The miniaturization of 3D vision components has made it feasible to incorporate this technology into smaller devices, including smartphones and handheld scanners. This has expanded its accessibility and potential applications.

- LiDAR Innovations:

LiDAR technology has become more compact and affordable, opening up new opportunities for 3D mapping, autonomous vehicles, and environmental monitoring.

Impact on Industries

The adoption of 3D machine vision has had a profound impact on multiple industries:

- Efficiency and Accuracy:

In manufacturing, 3D vision systems have significantly improved production efficiency by reducing defects and errors. Automated quality control systems ensure that products meet strict specifications, resulting in higher-quality products and reduced waste.

- Safety and Autonomy:

In the automotive and aerospace sectors, 3D vision technology has contributed to the development of autonomous vehicles and drones. These technologies have the potential to revolutionize transportation by enhancing safety, reducing accidents, and increasing efficiency.

- Precision Agriculture:

In agriculture, 3D machine vision has enabled precision farming techniques that optimize resource usage and crop yields. This not only benefits farmers but also has environmental benefits by reducing the use of pesticides and fertilizers.

- Healthcare Advancements:

In healthcare, 3D machine vision has revolutionized medical imaging and surgical procedures. It has enabled less invasive surgeries, shorter recovery times, and improved patient outcomes.

- Retail and E-commerce:

In the retail industry, 3D machine vision enhances customer experiences by enabling virtual try-ons and improving inventory management. E-commerce platforms use 3D technology to provide customers with a more immersive and accurate shopping experience.

Challenges and Future Directions

While 3D machine vision has made significant strides, several challenges and opportunities lie ahead:

- Cost: Implementing 3D vision systems can be expensive, especially for small businesses. Reducing the cost of hardware and software is crucial to wider adoption.

- Data Privacy and Security: As 3D vision systems become more prevalent, concerns about data privacy and security need to be addressed. Ensuring the responsible use of 3D data is essential.

- Environmental Impact: Some 3D vision technologies, such as LiDAR, require substantial energy consumption. Developing more energy-efficient solutions is important for sustainability.

- Integration and Standardization: To fully realize the potential of 3D machine vision, standards and protocols for interoperability between different systems need to be established.

- Ethical Considerations: As 3D vision becomes more integrated into society, ethical questions about its use, such as surveillance and data ownership, need to be addressed.

Conclusion

3D machine vision is at the forefront of technological innovation, transforming industries and revolutionizing the way we perceive and interact with the world. Its applications in manufacturing, healthcare, agriculture, automotive, retail, and aerospace are expanding rapidly, with each industry benefiting from increased efficiency, safety, and automation.

As technology continues to advance, addressing challenges related to cost, data privacy, and sustainability will be crucial. Additionally, ethical considerations surrounding the use of 3D vision technology must be carefully navigated to ensure responsible and equitable deployment.

With ongoing research and development, 3D machine vision is poised to continue its remarkable journey, bringing about further advancements and reshaping the landscape of various industries in the years to come. Visit official website qviro.com