In the world of automation, grippers play a crucial role in facilitating the interaction between robots and objects. A gripper is a mechanical device designed to grasp, hold, and manipulate objects, enabling robots to perform a wide range of tasks across various industries. Grippers are manufactured with precision and innovation, reflecting advancements in materials, design, and technology. This article delves into the world of gripper manufacturing, exploring key aspects of this industry and the transformative impact it has on automation. Amazon.com

Materials and Design

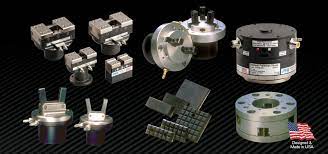

Gripper manufacturers invest heavily in research and development to create cutting-edge designs that maximize efficiency and versatility. One of the key considerations is the choice of materials. Grippers are often constructed from high-strength alloys, carbon fiber composites, and durable plastics. These materials provide the necessary strength-to-weight ratio, ensuring grippers can handle varying loads while remaining lightweight and agile.

Additionally, gripper design has evolved to accommodate a diverse range of objects. There are now specialized grippers tailored for delicate items like glassware, heavy-duty applications in industries like automotive manufacturing, and even grippers equipped with sensors for precise object recognition. Advanced engineering techniques such as additive manufacturing (3D printing) have further expanded the possibilities, allowing for intricate and customized gripper designs.

Technological Integration

Modern grippers are equipped with an array of sensors and actuators that enhance their functionality. Proximity sensors, force sensors, and vision systems allow grippers to adapt to the shape, size, and weight of objects, providing a level of dexterity previously unimaginable. These sensors provide real-time feedback to the robotic system, enabling adaptive gripping strategies and ensuring secure handling of objects with irregular shapes or varying textures.

Furthermore, the integration of artificial intelligence and machine learning algorithms has revolutionized gripper capabilities. Grippers can now learn from experience, adapting their grip strategy based on the success or failure of previous attempts. This level of adaptability is crucial in environments where objects may vary in size, shape, or texture, as it allows robots to perform tasks with a high degree of precision.

Customization and Adaptability

Gripper manufacturers recognize the importance of customization to meet the specific needs of various industries. They offer a range of modular gripper components that can be tailored to suit different applications. This versatility ensures that grippers can be easily integrated into existing robotic systems, minimizing downtime and maximizing operational efficiency.

Moreover, grippers are designed to be easily reconfigured or adapted for different tasks. Quick-change mechanisms and toolless adjustment systems enable operators to switch between different gripper configurations swiftly. This adaptability is crucial in industries where production lines may need to accommodate a wide variety of products.

Safety and Compliance

Safety is a paramount concern in automation, and gripper manufacturers are committed to ensuring that their products meet stringent safety standards. Grippers are equipped with features such as collision detection and force-limiting mechanisms to prevent damage to both the gripper and the objects being handled. In environments where human-robot collaboration is prevalent, grippers are designed to meet collaborative robot safety standards, ensuring the well-being of human operators.

Environmental Considerations

As sustainability becomes an increasingly important factor in manufacturing, gripper manufacturers are exploring eco-friendly materials and production processes. Many are adopting practices that minimize waste and reduce energy consumption during manufacturing. Additionally, manufacturers are designing grippers with longevity in mind, using durable materials that can withstand years of use without degradation.

Conclusion

The world of gripper manufacturing is a dynamic and innovative field that plays a pivotal role in advancing automation across industries. Through continuous research and development, manufacturers are pushing the boundaries of what is possible, creating grippers that are more versatile, adaptable, and efficient than ever before. By prioritizing materials, design, technology integration, customization, safety, and environmental considerations, gripper manufacturers are driving the automation revolution, enabling robots to perform tasks with unprecedented precision and reliability. As this industry continues to evolve, we can expect even more groundbreaking developments that will shape the future of automation. Visit official website qviro.com