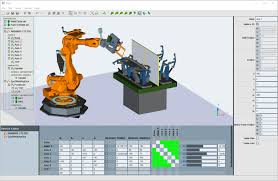

Robot simulation software stands at the forefront of modern technological advancements, offering a dynamic platform to emulate, analyze, and refine the behavior of robotic systems. This innovative tool has become indispensable across a wide array of industries, including manufacturing, healthcare, logistics, and even space exploration. In this essay, we will delve into the world of robot simulation software, exploring its applications, benefits, and the profound impact it has on shaping the future of automation.Wikipedia.org

I. Applications of Robot Simulation Software

- Manufacturing and Assembly Lines

Robot simulation software finds its roots in the manufacturing industry, where precision, efficiency, and repeatability are paramount. By virtually replicating assembly processes, engineers can fine-tune robot movements, optimize workflows, and even experiment with different robot configurations to achieve optimal production output.

- Healthcare and Medical Robotics

In the medical field, precision is a matter of life and death. Robot simulation software allows for realistic testing of surgical procedures, rehabilitation exercises, and the development of assistive devices. This ensures that robots operate with the utmost accuracy and safety when interacting with patients.

- Logistics and Warehousing

The logistics sector has witnessed a surge in automation, driven by the demand for faster and more efficient distribution processes. Robot simulation software helps in designing and testing autonomous vehicles, robotic arms for picking and packing, and entire warehouse layouts to maximize throughput.

- Aerospace and Space Exploration

Simulating robots for space missions is a crucial step in ensuring their success. From rovers exploring distant planets to autonomous repair drones in space stations, simulation software aids in verifying the reliability and effectiveness of these systems in environments where human intervention is often impractical.

II. Benefits of Robot Simulation Software

- Cost-Effectiveness

Building and testing physical prototypes can be prohibitively expensive and time-consuming. Robot simulation software drastically reduces these costs by allowing engineers to iterate and refine designs virtually before committing to physical production.

- Risk Mitigation

In industries where safety is paramount, such as healthcare and aerospace, ensuring that robots operate flawlessly is critical. Simulation software enables engineers to identify and rectify potential issues in a controlled environment, minimizing the risk of accidents or failures in real-world scenarios.

- Optimization and Efficiency

Through iterative testing and analysis, simulation software empowers engineers to fine-tune robot behavior for maximum efficiency. This can lead to improvements in cycle times, resource utilization, and overall system performance.

- Training and Education

Robot simulation software serves as a valuable tool for training operators, programmers, and maintenance personnel. It provides a safe environment for learning and experimentation, allowing individuals to gain hands-on experience without the risks associated with live equipment.

III. Key Features of Robot Simulation Software

- Realistic Physics Engines

Advanced simulation platforms incorporate realistic physics engines that accurately model the interactions between robots and their environments. This allows for precise predictions of robot behavior, including factors such as collisions, friction, and inertia.

- Multi-Robot Coordination

Many applications involve the coordination of multiple robots working together. Simulation software enables engineers to study and optimize the interactions between these robots, ensuring seamless cooperation and synchronization.

- Sensor and Perception Modeling

To mimic real-world scenarios, simulation software often includes the ability to model various sensors such as cameras, LiDAR, and proximity sensors. This allows engineers to test and refine perception algorithms under diverse conditions.

- Integration with Control Systems

Seamless integration with robot control systems and programming environments is crucial for validating code and algorithms. Simulation software often provides interfaces for direct interaction with the robot's control software, facilitating easy code testing and debugging.

Conclusion

Robot simulation software has emerged as an indispensable tool in modern engineering and automation. Its applications span across diverse industries, offering a cost-effective, risk-mitigating, and efficiency-boosting platform for designing and refining robotic systems. As technology continues to advance, the role of simulation software in shaping the future of automation will undoubtedly become even more profound. By harnessing the power of virtual emulation, engineers are paving the way for a new era of precision, safety, and innovation in robotics. Visit official website qviro.com