In the realm of modern manufacturing and industry, a groundbreaking innovation has emerged over the past few decades - Collaborative Robots, often referred to as Cobots. These advanced robotic systems have transformed the way we perceive automation and human-robot interaction, ushering in a new era of productivity, safety, and efficiency. In this comprehensive exploration, we will delve into the world of Cobots, uncovering their history, technology, applications, advantages, challenges, and their potential impact on various sectors. Amazon.com

I. Introduction to Collaborative Robots (Cobots)

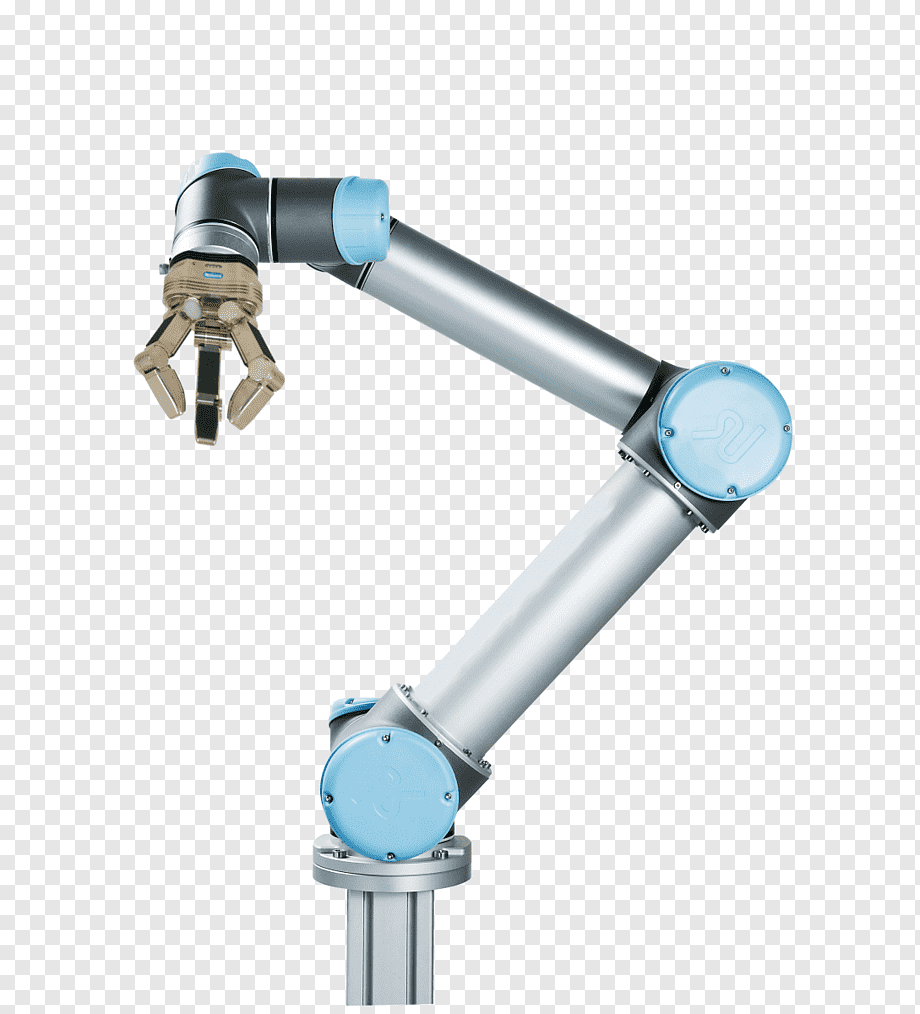

Collaborative Robots, or Cobots, are a class of robotic systems designed to work alongside humans in a shared workspace. Unlike traditional industrial robots that typically operate in isolation behind safety barriers, Cobots are specifically engineered to interact safely and effectively with human workers. The primary objective of Cobots is to augment human capabilities, improve efficiency, and enhance safety in various industries.

II. The Evolution of Cobots: A Brief History

The concept of Cobots dates back to the mid-20th century, but their practical realization and widespread adoption are relatively recent phenomena. Key milestones in the evolution of Cobots include:

- Early Experiments (1940s-1960s): Researchers began exploring the idea of human-robot collaboration during this period, but technology limitations hindered their progress.

- Automated Guided Vehicles (AGVs): AGVs, introduced in the 1950s, represented early forms of automation in material handling. While not true Cobots, they laid the groundwork for more advanced collaboration.

- First Cobot Prototypes (1990s): The 1990s saw the development of rudimentary Cobots with basic safety features. However, they were not widely adopted due to limited functionality and high costs.

- Modern Cobots (2000s - Present): Advances in robotics, sensors, and artificial intelligence in the early 21st century revolutionized the field of Cobots. Companies like Universal Robots, Rethink Robotics (now defunct), and others played pivotal roles in making Cobots commercially viable. These robots feature advanced safety mechanisms, ease of programming, and adaptability, which significantly expanded their applications. Read more about what are cobots

III. Key Technologies Behind Cobots

Cobots owe their capabilities to a combination of cutting-edge technologies, making them versatile, safe, and easy to work with:

- Sensors: Cobots are equipped with various sensors, including vision systems, force/torque sensors, and proximity sensors, allowing them to perceive their environment and interact with objects and humans.

- Machine Learning and AI: Artificial intelligence and machine learning algorithms enable Cobots to adapt to changing tasks, learn from their interactions, and make decisions in real-time.

- Safety Features: Advanced safety features like speed and force limiting, collision detection, and the ability to stop or slow down when a human enters their workspace ensure safe collaboration.

- User-Friendly Programming: Cobots are designed with user-friendliness in mind, often using intuitive interfaces that allow even non-experts to program and deploy them.

IV. Applications of Cobots

Cobots have found applications across a wide range of industries, including manufacturing, healthcare, logistics, agriculture, and more. Some notable applications include:

- Manufacturing: In manufacturing, Cobots are used for tasks such as pick-and-place, assembly, quality control, and machine tending. They can work alongside human operators on factory floors, increasing productivity and flexibility.

- Healthcare: Cobots assist in healthcare settings by handling delicate and repetitive tasks, such as medication dispensing, patient lifting, and surgical assistance. They reduce the physical strain on healthcare professionals and improve patient care.

- Logistics and Warehousing: In logistics and warehousing, Cobots are employed for tasks like order picking, packing, and material transport. They help streamline operations and reduce the risk of injuries related to heavy lifting.

- Agriculture: Cobots are used in agriculture for tasks like planting, harvesting, and weeding. They can work tirelessly and precisely in challenging outdoor environments, increasing agricultural efficiency.

- Research and Education: Cobots are also valuable tools in research and education. They provide hands-on experience for students and researchers in robotics and automation.

V. Advantages of Cobots

The adoption of Cobots offers numerous advantages to businesses and industries:

- Increased Efficiency: Cobots can work around the clock without fatigue, leading to improved productivity and reduced production costs.

- Improved Safety: With built-in safety features and the ability to work closely with humans, Cobots reduce the risk of workplace accidents.

- Flexibility: Cobots are highly adaptable and can be easily reprogrammed to perform different tasks, allowing businesses to respond quickly to changing production demands.

- Cost-Effectiveness: Compared to traditional industrial robots, Cobots are often more affordable to purchase, install, and maintain.

- Enhanced Quality: Cobots can consistently perform tasks with precision, leading to higher product quality and reduced defects.

- Workforce Augmentation: Rather than replacing human workers, Cobots complement them, allowing employees to focus on more complex and value-added tasks.

VI. Challenges and Limitations

While Cobots offer numerous benefits, they also face several challenges and limitations:

- Cost: The initial investment in Cobots can be substantial, making them less accessible to small and medium-sized businesses.

- Complex Integration: Integrating Cobots into existing workflows and systems can be a complex process, requiring specialized expertise.

- Limited Payload and Speed: Cobots typically have lower payload capacities and slower speeds compared to traditional industrial robots, limiting their applicability in certain tasks.

- Programming Complexity: Despite user-friendly interfaces, programming Cobots for complex tasks may still require advanced technical skills.

- Safety Concerns: While Cobots are designed to be safe, accidents can still occur if proper safety protocols are not followed.

VII. The Future of Cobots

The future of Cobots appears promising, with ongoing advancements in technology and growing demand for automation and collaboration. Several trends and developments are shaping their future:

- AI and Learning Abilities: Cobots will continue to become more intelligent, capable of learning and adapting to new tasks independently.

- Cost Reduction: As technology matures and economies of scale come into play, the cost of Cobots is expected to decrease, making them more accessible to a broader range of industries.

- Customization: Cobots will become increasingly customizable to suit specific industry needs, with modular designs that allow for easy upgrades.

- Collaborative Ecosystems: Companies will develop collaborative ecosystems where Cobots work seamlessly with other automation technologies like drones, AGVs, and IoT devices.

- New Applications: As technology evolves, new applications for Cobots will emerge in fields such as construction, mining, and retail.

VIII. Conclusion

Collaborative Robots, or Cobots, have ushered in a new era of human-robot interaction and automation. They offer significant advantages in terms of efficiency, safety, and flexibility, making them valuable assets across various industries. While they face challenges and limitations, ongoing technological advancements promise an even more exciting future for Cobots, with the potential to revolutionize how we work and produce goods in the years to come. visit official website qviro.com