In the world of commercial and industrial roofing, TPO (Thermoplastic Olefin) roofing systems have gained significant popularity over the years. TPO roofs are known for their durability, energy efficiency, and ease of installation. This article delves into the details of what a TPO roof is, its characteristics, benefits, and the installation process. Alibaba.com

Understanding TPO Roofing

TPO, short for Thermoplastic Olefin, is a synthetic roofing material that falls under the category of single-ply membranes. It was first introduced in the 1980s as an alternative to PVC (Polyvinyl Chloride) and EPDM (Ethylene Propylene Diene Monomer) roofing systems. TPO roofing is composed of a blend of polypropylene and ethylene-propylene rubber, reinforced with polyester or fiberglass. The result is a highly flexible and durable roofing membrane that is suitable for a wide range of applications.

Characteristics of TPO Roofing

- Durability: TPO roofing is known for its resilience against weather elements. It can withstand extreme temperatures, UV radiation, and chemical exposure without deteriorating. This durability makes it an excellent choice for areas prone to harsh weather conditions.

- Energy Efficiency: TPO roofs are often white or light-colored, which helps in reflecting sunlight and heat away from the building. This reflective property can significantly reduce cooling costs, making TPO roofing an energy-efficient choice.

- Flexibility: TPO membranes are highly flexible, making them easy to install on roofs with irregular shapes or complicated designs. The flexibility also allows the roof to expand and contract with temperature changes without causing damage.

- Resistance to Tears and Punctures: TPO roofing is resistant to tears and punctures, which is crucial for maintaining its integrity over the years. This resistance reduces the likelihood of leaks and costly repairs.

- Environmentally Friendly: TPO roofing is considered environmentally friendly because it is recyclable and can be repurposed at the end of its lifespan. Additionally, its energy-efficient properties contribute to a reduced carbon footprint. Read more about What is a TPO Roof?

Benefits of TPO Roofing

- Cost-Effective: TPO roofing is cost-effective in terms of both installation and maintenance. It is generally less expensive than some other roofing materials, and its long lifespan reduces the need for frequent repairs and replacements.

- Energy Savings: As mentioned earlier, TPO roofing's reflective surface can lead to significant energy savings by reducing cooling costs. This makes it an excellent choice for environmentally conscious building owners.

- Easy Installation: TPO roofing is relatively easy to install, which can save on labor costs and reduce installation time. Its lightweight nature also puts less stress on the building's structure.

- Versatility: TPO roofing can be used on a wide range of building types, from commercial and industrial facilities to residential properties. Its versatility makes it a versatile choice for various applications.

- Longevity: When properly installed and maintained, TPO roofs can last for 20-30 years or more. This long lifespan provides excellent value for the initial investment.

Installation Process of TPO Roofing

Installing a TPO roof requires precision and expertise. Here is an overview of the typical installation process:

- Surface Preparation: The first step involves preparing the roof's surface by cleaning it thoroughly and ensuring it is free from debris, dirt, and any previous roofing material. Any existing issues or damage should be repaired at this stage.

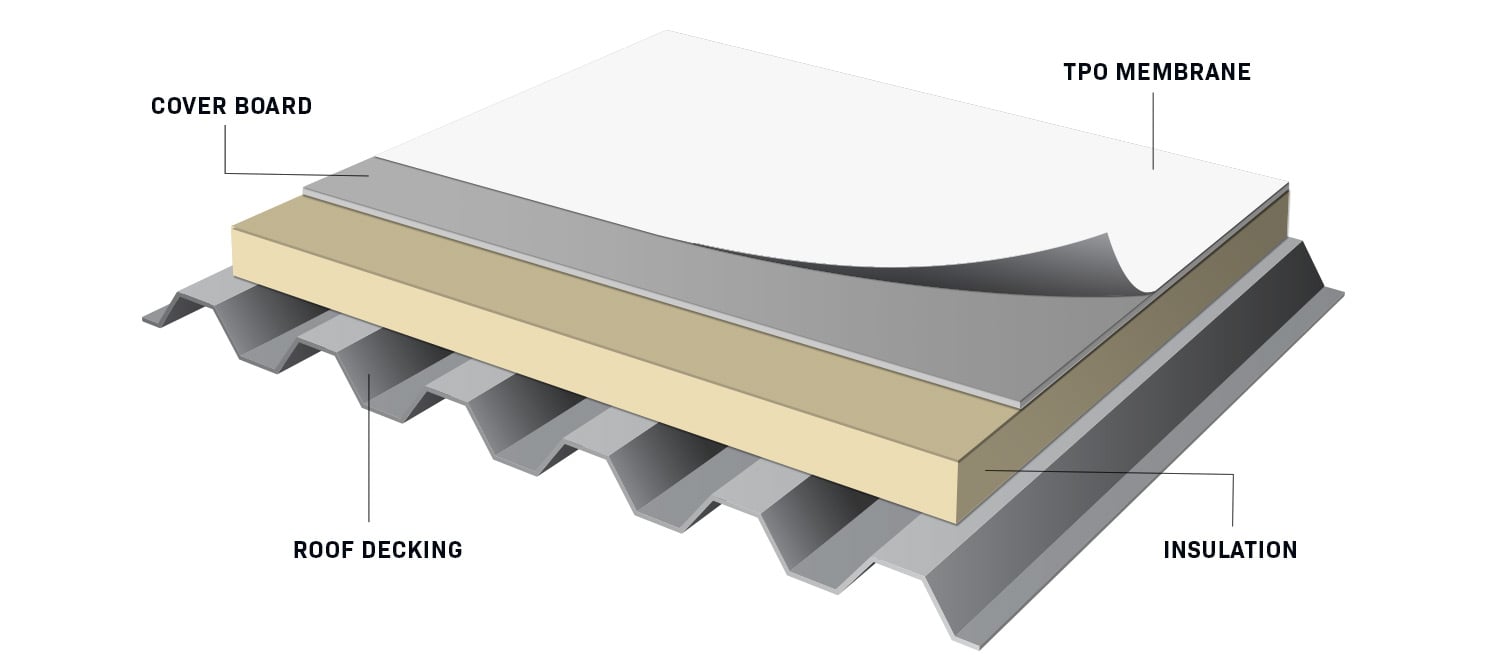

- Insulation: A layer of insulation is installed to improve the roof's energy efficiency and provide thermal resistance. Proper insulation helps maintain a consistent indoor temperature.

- Attachment: The TPO membrane is attached to the roof's surface using one of two methods: mechanically fastened or fully adhered. In the mechanically fastened method, the membrane is secured to the roof deck with screws and plates. In the fully adhered method, adhesive is applied to the insulation or roof deck, and the membrane is bonded to it.

- Seaming: Seams are a critical aspect of TPO roofing installation. Heat welding or chemical adhesive is used to create strong and watertight seams between membrane sheets. Properly sealed seams are crucial to preventing leaks.

- Flashing Installation: Flashing is installed around roof penetrations such as vents, pipes, and HVAC units to ensure a watertight seal. Properly installed flashing is essential for the roof's overall integrity.

- Quality Inspection: After the installation is complete, a thorough inspection is carried out to check for any defects, imperfections, or areas that may require additional attention.

- Final Cleanup: The job is finalized with a cleanup to remove any debris and ensure the work area is left clean and safe.

Conclusion

TPO roofing systems have become a popular choice for both commercial and industrial buildings due to their durability, energy efficiency, and cost-effectiveness. These roofs offer numerous benefits, including long-term savings on energy costs and a reduced environmental footprint. When installed correctly, TPO roofs can provide decades of reliable protection for a wide range of structures. With their flexibility, resistance to weather elements, and ease of installation, TPO roofing systems are likely to continue their prominence in the roofing industry for years to come. Visit official website onlyroofing.com