When it comes to RC vehicles, cars, or any type of mobile machine, the chassis serves as the foundation—the structural frame upon which all other components are mounted. From rigid performance platforms to flexible crawling frames, the design, material, and configuration of a chassis determine not only durability and strength but also handling, stability, and performance. In this comprehensive guide, we delve into the importance of chassis, explore various types, discuss materials, and highlight top choices in the RC and automotive industry.

What is a Chassis? Understanding Its Core Function

The chassis is the main structural component that supports and connects all other parts of a vehicle, such as the engine, drivetrain, suspension, electronics, and body panels. In RC vehicles, the chassis also acts as a mounting base for motors, batteries, servos, and ESCs.

Key Functions of a Chassis:

- Structural Integrity: Provides the rigid framework needed to maintain the shape and balance of the vehicle.

- Load Distribution: Effectively distributes the weight and stress from impacts or rough terrain.

- Component Housing: Offers mounting points and protection for essential components.

- Performance Optimization: A well-designed chassis enhances handling, traction, and stability.

Types of Chassis: Selecting the Right Framework

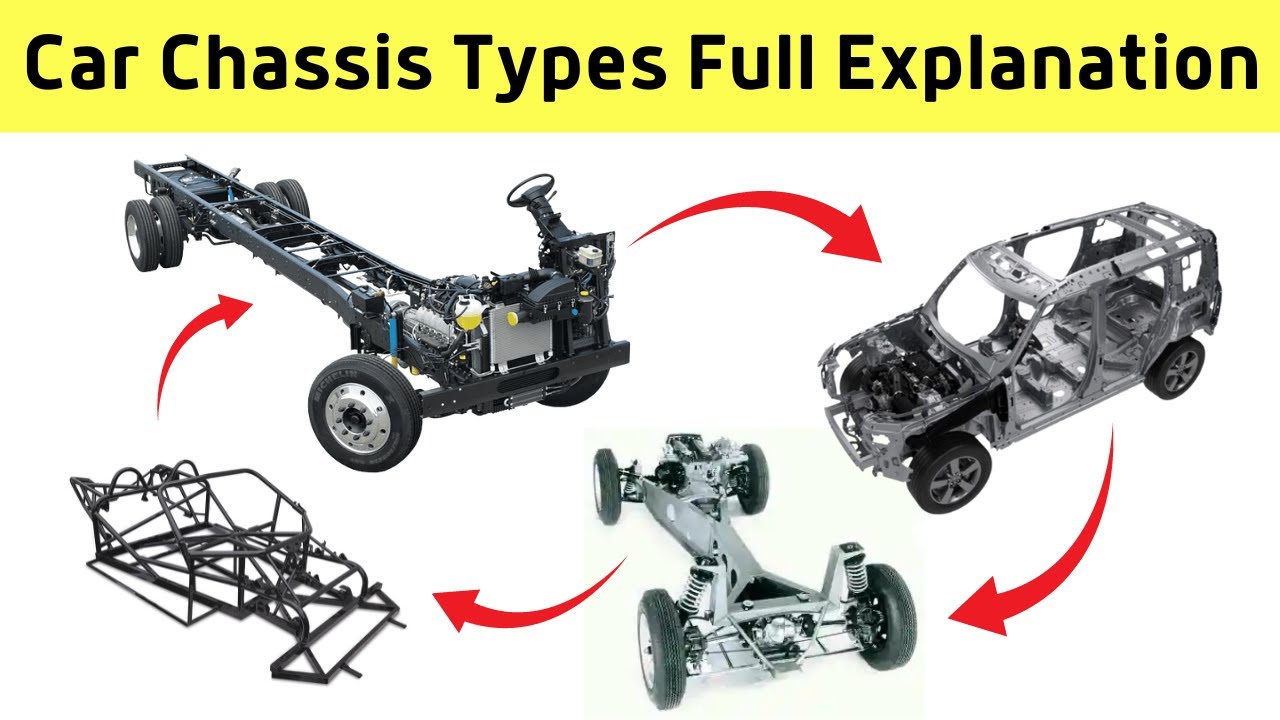

1. Ladder Frame Chassis

- Found in trucks and crawlers.

- Comprises two longitudinal rails connected by lateral supports.

- Offers excellent strength and flexibility for off-road applications.

2. Tubular Chassis

- Built using metal tubes in a truss configuration.

- Provides exceptional strength-to-weight ratio.

- Common in race buggies and custom builds.

3. Monocoque Chassis

- Integrated frame and body structure.

- Popular in on-road cars and racing platforms.

- Offers lightweight rigidity and aerodynamic advantages.

4. Carbon Fiber Plate Chassis

- Flat chassis design made from carbon fiber sheets.

- Ideal for lightweight, high-speed applications like drift cars and touring cars.

- Known for precision handling and rigid performance.

Chassis Materials: Strength, Weight, and Performance

1. Aluminum

- Lightweight, corrosion-resistant, and strong.

- Offers heat dissipation, making it suitable for racing and high-speed use.

- Common in 1/10 and 1/8 scale RC cars.

2. Carbon Fiber

- Ultra-light and extremely rigid.

- Ideal for competitive racing where every gram matters.

- Resistant to bending and warping under stress.

3. Steel

- Heavy but immensely strong.

- Used in crawlers and heavy-duty RC vehicles for maximum durability.

- Handles extreme impacts and rock crawling abuse.

4. Plastic/Composite

- Lightweight and cost-effective.

- Found in entry-level RC vehicles.

- Provides flexibility but less durable under high stress.

Chassis Design and Its Impact on Performance

Weight Distribution

An optimally designed chassis ensures balanced weight distribution, which improves traction, acceleration, and cornering stability.

Flexibility vs. Rigidity

- Crawlers benefit from flexible chassis designs that allow for articulation over rocks and uneven terrain.

- Racers require rigid chassis for high-speed stability and precise control.

Low Center of Gravity (LCG)

Many modern chassis are designed with an LCG setup to improve handling and reduce rollovers, particularly in on-road and short-course trucks.

Top Chassis Kits for RC Enthusiasts

1. Axial SCX10 III Chassis

- Ladder frame chassis for scale crawlers.

- Offers realistic suspension geometry and modular design.

2. Traxxas Slash LCG Chassis

- Designed for short-course racing.

- Features lowered ride height for cornering control and speed.

3. Tamiya TT-02 Chassis

- Entry-level on-road chassis.

- Balanced for versatility, durability, and upgradability.

4. Team Associated B6.4 Chassis

- Built for competitive 1/10 buggy racing.

- Lightweight carbon fiber construction with precision tuning options.

Custom Chassis: Build to Suit

Custom chassis fabrication allows hobbyists to tailor their vehicles for specific needs, whether it's rock crawling, drag racing, or trail running. Custom chassis kits offer modular design, adjustable mounting points, and material choices to suit any terrain or racing condition.

Maintenance Tips for Chassis Longevity

- Inspect Regularly: Check for cracks, bends, or loose screws.

- Clean After Use: Remove mud, dirt, and debris to avoid wear.

- Check Mounting Points: Ensure components remain securely attached.

- Upgrade Wisely: Consider reinforced materials or braces for added durability.

Conclusion: The Chassis is Your Vehicle’s Foundation

A well-designed chassis is the cornerstone of vehicle performance. It supports, protects, and enhances every function of your custom RC cars or full-sized vehicle. Whether you’re navigating rugged trails, hitting the racing circuit, or crafting a custom build, investing in the right chassis will significantly impact durability, performance, and overall success.