Since my last blog entry, I have made some headway into working towards a full restoration. Though it took a bit of time going from one book to another and searching the giant blackhole of information that is the internet, I have managed to find a copy of the original leaflet that goes with this Dryad loom. Although it is coming a long way across the big pond known as the Atlantic from the good Ol' US of A. So that said it is going to be a little time before it arrives, likely at the end of the month or early next.

However, I also found many pictures of the same loom and all set up, and it was clear that there were bits missing that would need replacing, either bought, or made up in my workshop.

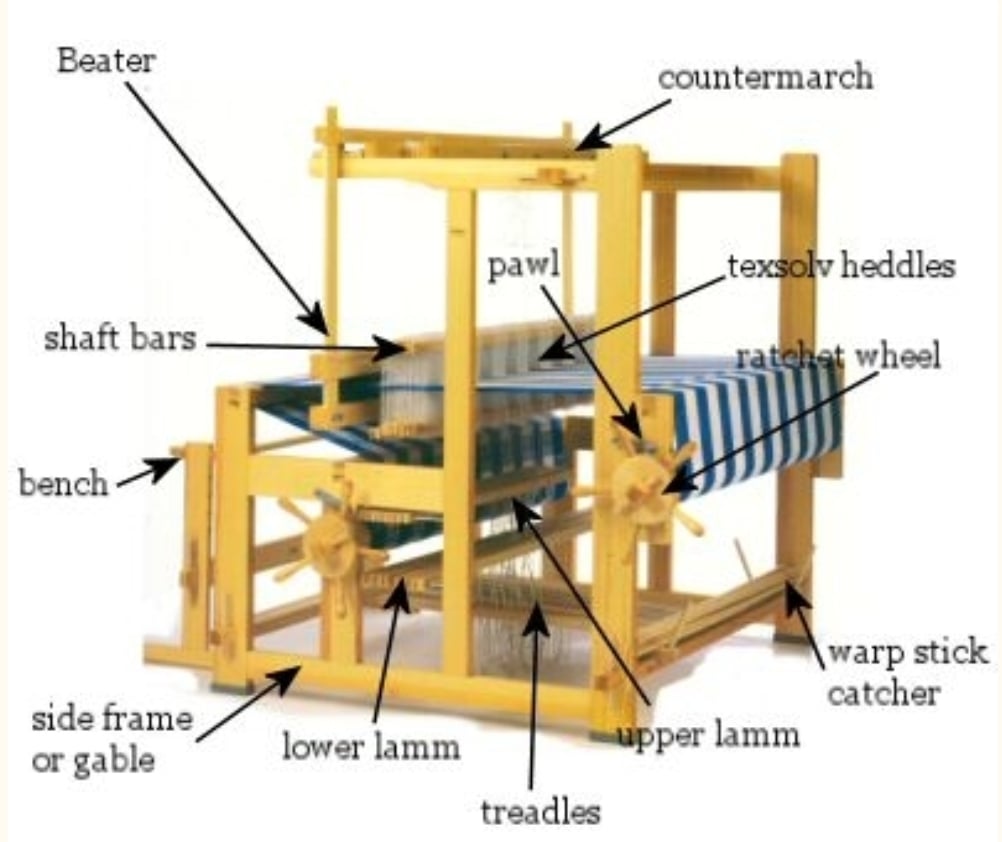

The most obvious of these is the heddles, a key component of any loom. These are what hold all the warp threads in place and allow you to manipulate their respective position.

These are often hundreds of ties with a centre loop between two bars of wood or a frame metal heddles that can be moved up and down by pushing the peddles with your feet. Depending on how they are arranged and tied on, this creates the opening between the warp called the shed warp threads. This is where the weft is passed through, then the warp is manipulated into a different position, locking in the weft and opening another shed for the weft, and this is the fundamental aim of weaving on a loom.

OK, so I'm going to need some heddles great, but wait, how do they attach to the loom? How do you manipulate them into their respective positions. Well, you're quite right to ask such questions they don't just float in space by themselves. The Heddles are suspended from above by hanging down from the top beam that has so many names as there are different looms, the arch, coutermarch, upright, and castle shelf, and you could go on.

For my loom, I'll just call it the top beam. The top beam should have two pulleys on the bottom side, which the horses are attached between two horses per pulley, i have these fortunately The horses are suspended at the ends of a length of braid or cord, which goes over the pulley. Each horse has a hole at each end, four horses with two holes in each over two pulleys. This allows for 4 heddles to be suspended from the a horse on either side of the loom where the pulleys are. This is a four shaft loom. Looms come in all sizes with 8 shafts and 12 shafts, etc

But wait what about the lamms? The lamms you say?? What are the lamms? Well, these are bars that are horizontal to the front length of the loom and are positioned below the heddles and above the treadle peddles. These are also missing from my loom. These are all part of the essential mechanism that allow you to manipulate different heddles in different orders when tied to the peddles below in different orders.

So, these are the main items I've identified at this stage that I will need to source or fabricate, the two pulleys, the heddles, and supporting bars or frame, the lamms. This gives me a good starting point, and once I've made or found each part to replace, then I'll focus on cleaning up and finishing up the wood with some sort of finish to preserve the loom.

Hopefully, in another week or so, I can give an update on my progress.

Until then, all the best, and thanks for following my page. Wolfie 🐺

N.b. the picture shown is not the same loom as mine but the terminology for the parts are relevant and in much the same positioning, with a few noticeable differences. The beater is attached from above not the base, as is the case with my loom.