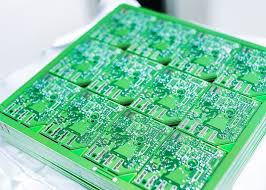

In today’s fast-paced electronics industry, advanced PCB assembly plays a crucial role in bringing high-performance devices to life. Whether it's a smartphone, medical equipment, or an industrial automation system, the foundation of every sophisticated device lies in a precisely assembled printed circuit board (PCB).

Advanced PCB assembly goes beyond traditional soldering and component placement. It involves high-density interconnect (HDI) technology, surface-mount technology (SMT), through-hole mounting, and even multi-layer board fabrication. These techniques allow for smaller, more powerful, and energy-efficient products that can meet the complex demands of modern applications.

What sets advanced PCB assembly apart is its precision, speed, and reliability. Automated pick-and-place machines, reflow soldering, and 3D AOI (Automated Optical Inspection) ensure that each component is perfectly aligned and bonded. This results in boards that not only function flawlessly but also stand the test of time in demanding environments.

Moreover, as the demand for smart devices and IoT products increases, so does the need for custom, high-speed, and flexible PCB solutions. Advanced PCB assembly providers offer end-to-end support—from prototyping and small batch runs to full-scale production—making innovation faster and more scalable than ever.

In conclusion, Advanced PCB assembly is not just a manufacturing step; it’s the backbone of modern electronics innovation. By integrating cutting-edge techniques and stringent quality controls, it helps companies launch reliable, next-gen products quickly and efficiently.

#PCBAssembly #AdvancedElectronics #SMT #PCBManufacturing #ElectronicsIndustry #IoT #TechInnovation