In the fast-paced world of electronics, innovation begins at the circuit level. Advanced PCB (Printed Circuit Board) Assembly is at the heart of today’s most complex electronic devices, enabling higher performance, miniaturization, and seamless integration of technologies. From medical devices to aerospace systems, advanced PCB assembly plays a critical role in making modern technology smarter, faster, and more efficient.

What Is Advanced PCB Assembly?

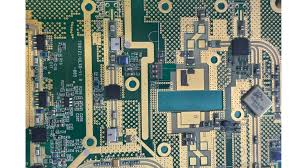

Advanced PCB assembly refers to the manufacturing process where intricate components are precisely mounted on complex, multilayer printed circuit boards. Unlike basic assembly processes, it involves high-density interconnect (HDI) boards, fine-pitch components, BGA (Ball Grid Array) packages, and surface-mount technology (SMT). These features allow for more functionality within a compact space — a necessity in devices like smartphones, IoT gadgets, wearables, and automotive electronics.

Key Technologies in Advanced PCB Assembly

- Surface Mount Technology (SMT) – SMT allows for automatic placement of small components with high accuracy, ensuring fast, reliable assembly.

- Reflow Soldering & Vapor Phase Soldering – These techniques ensure solid, defect-free solder joints even in high-density boards.

- X-ray Inspection & AOI (Automated Optical Inspection) – These quality control tools detect faults invisible to the naked eye, guaranteeing the integrity of the assembly.

- BGA & Fine-Pitch Component Handling – These techniques handle ultra-small components and complex ICs used in high-end applications.

- Multi-layer Board Fabrication – Supports complex routing needed for advanced computing and RF applications.

Industries That Rely on Advanced PCB Assembly

- Medical: Devices like pacemakers and diagnostic equipment require ultra-reliable and compact PCBs.

- Automotive: Electric vehicles and ADAS systems depend on robust, high-density PCBs.

- Aerospace: Demands extreme durability and precision under harsh conditions.

- Consumer Electronics: Smartphones, smartwatches, and AR/VR devices rely on advanced assembly for compact functionality.

Conclusion

Advanced PCB assembly is the cornerstone of next-generation electronics. It transforms ideas into reality, enabling engineers to push the boundaries of what's possible. Whether you're developing wearable tech or aerospace systems, investing in high-quality PCB assembly is not just smart — it’s essential.