Printed Circuit Board Assembly (PCBA) is the heart of almost every electronic device we use today. From smartphones and laptops to medical equipment and automotive systems, PCBA ensures that electronic circuits function efficiently and reliably. But what exactly is PCBA, and why is it so crucial?

Understanding PCBA

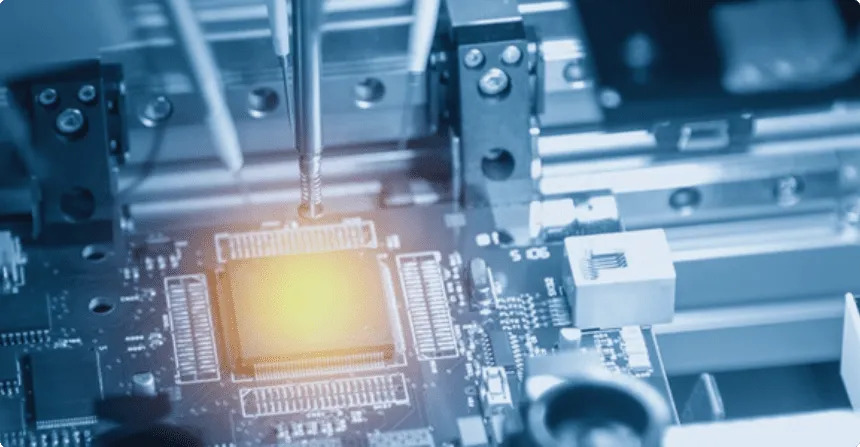

Printed Circuit Board Assembly refers to the process of mounting electronic components onto a printed circuit board (PCB). While the PCB itself is just the board with copper tracks, once components like resistors, capacitors, integrated circuits (ICs), and connectors are soldered onto it, it becomes a fully functional assembly ready to power devices.

The assembly process can involve manual soldering for simpler circuits or automated machines for complex, high-volume production. The main techniques used are Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT involves placing components directly onto the surface of the board, while THT involves inserting component leads into holes drilled in the board and soldering them in place.

Steps in the PCBA Process

- Solder Paste Application: Solder paste is applied to areas of the PCB where components will be placed.

- Component Placement: Using pick-and-place machines, components are positioned accurately on the board.

- Soldering: Reflow soldering is used for SMT components, and wave soldering is often used for THT components.

- Inspection and Quality Control: Advanced inspection methods like Automated Optical Inspection (AOI) and X-ray Inspection ensure there are no defects.

- Functional Testing: Final tests verify that the PCB assembly works as intended before it is installed in the final product.

Importance of High-Quality PCBA

A high-quality PCBA ensures the reliability, durability, and performance of an electronic device. Faulty assemblies can lead to device malfunctions, safety hazards, and high costs due to recalls or repairs. That’s why professional PCBA services prioritize precision, quality control, and the use of top-grade components.

Choosing the Right PCBA Partner

When looking for a PCBA service provider, it’s important to consider factors like their certifications (such as ISO 9001 and IPC standards), production capabilities, turnaround time, and support for prototyping and low-volume runs. A reliable partner can help bring innovative designs to life and ensure seamless manufacturing processes.

Conclusion

Printed Circuit Board Assembly is a critical step in the electronics manufacturing process. It transforms a simple board into a powerful, functional foundation for modern technology. As devices continue to get smarter and more complex, the importance of expert PCBA services will only grow. Whether you're developing consumer gadgets, industrial systems, or medical devices, a strong focus on PCB assembly quality can make all the difference.