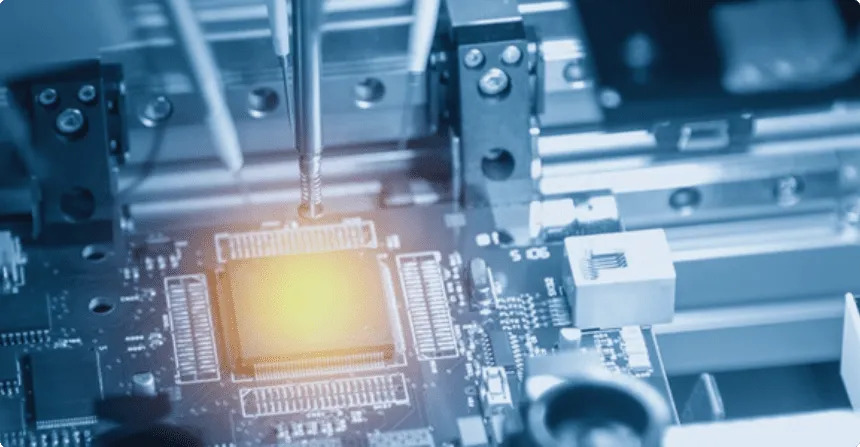

Printed Circuit Board Assembly (PCBA) is a critical process in modern electronics manufacturing, where electronic components are mounted onto a pre-manufactured printed circuit board (PCB). This process transforms a bare board into a functional and ready-to-use electronic device — whether it’s for a smartphone, medical equipment, or automotive system.

Printed Circuit Board Assembly PCBA involves multiple precise and technical steps, including solder paste application, component placement, soldering (usually through reflow or wave soldering), inspection, and functional testing. Each step is crucial to ensure the reliability and performance of the final product.

There are two major types of assembly technologies used: Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT is widely used due to its speed, efficiency, and ability to place small components with high density, while THT provides robust mechanical bonding and is ideal for components that endure mechanical stress.

Quality control in PCBA is essential. Automated Optical Inspection (AOI), X-ray inspection, and In-Circuit Testing (ICT) help detect soldering defects, misalignments, or faulty components. These checks ensure that every board meets strict industry standards before deployment.

Choosing the right Printed Circuit Board Assembly PCBA service provider is equally important. Look for experienced manufacturers that offer end-to-end solutions — from prototyping and small batch runs to large-scale production. Reliable partners also provide Design for Manufacturability (DFM) feedback to help optimize your PCB designs.

In today’s fast-evolving tech landscape, efficient and high-quality PCB assembly is the backbone of innovation. Whether you're developing consumer electronics, industrial machinery, or IoT devices, a solid PCBA process ensures your products function flawlessly and reach the market faster.