Summit Interconnect CA – Driving Medical Electronics Forward with Precision PCBs

In the world of medical technology, precision and reliability are paramount. Devices used in diagnostics, monitoring, and treatment must perform flawlessly under critical conditions. Summit Interconnect CA has become a key player in this space by providing advanced printed circuit board (PCB) solutions tailored to the unique demands of medical electronics. Their expertise in complex rigid, flex, and rigid-flex PCBs enables the development of compact, high-performance devices that improve patient outcomes and advance healthcare innovation.

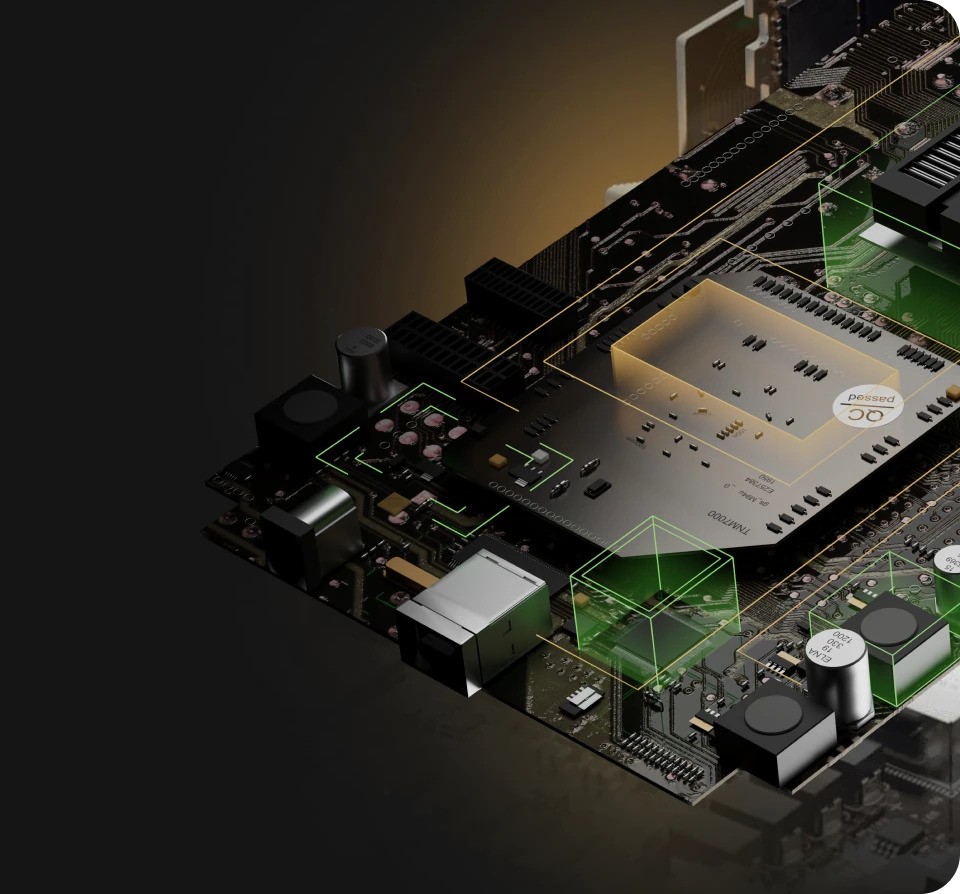

Medical devices often require miniaturized electronics that can operate reliably in confined spaces and under continuous use. Summit Interconnect’s rigid-flex PCBs are ideal for such applications, offering the structural integrity of rigid boards with the adaptability of flexible circuits. This combination allows for three-dimensional configurations that reduce the need for connectors and cables, enhancing both reliability and design flexibility.

Summit’s engineering team works closely with medical device manufacturers to develop custom PCB solutions that meet stringent regulatory and performance standards. Their ability to produce multilayer boards with controlled impedance, blind and buried vias, and advanced materials ensures that each circuit functions optimally in its intended environment. Whether it’s a wearable health monitor, a surgical instrument, or an implantable device, Summit’s PCBs are built to deliver consistent performance.

The company’s manufacturing facilities in California are equipped with cutting-edge technologies that support precision fabrication and inspection. Laser direct imaging (LDI), automated optical inspection (AOI), and X-ray analysis are just a few of the tools used to ensure that every board meets exacting specifications. Summit’s commitment to quality is further demonstrated by its ISO 9001 and AS9100 certifications, as well as ITAR compliance for sensitive applications.

In addition to manufacturing excellence, Summit Interconnect CA offers comprehensive design support and engineering consultation. Their experts assist clients in optimizing layouts, selecting biocompatible materials, and refining stack-ups to enhance manufacturability and performance. This collaborative approach reduces development time and ensures that each PCB is tailored to the specific needs of the medical device.

Summit’s rigid-flex capabilities are particularly valuable in wearable and implantable technologies, where space is limited and reliability is critical. Their ability to produce boards with tight bend radii and adhesiveless laminates enables the creation of flexible electronics that conform to the human body without compromising functionality. These innovations are helping drive the next generation of medical devices that are smaller, smarter, and more effective.

As the medical industry continues to embrace digital transformation, Summit Interconnect CA remains at the forefront of PCB innovation. Their dedication to engineering precision, quality assurance, and customer collaboration makes them a trusted partner for companies developing life-saving technologies. With each circuit they produce, Summit contributes to a healthier, more connected world.