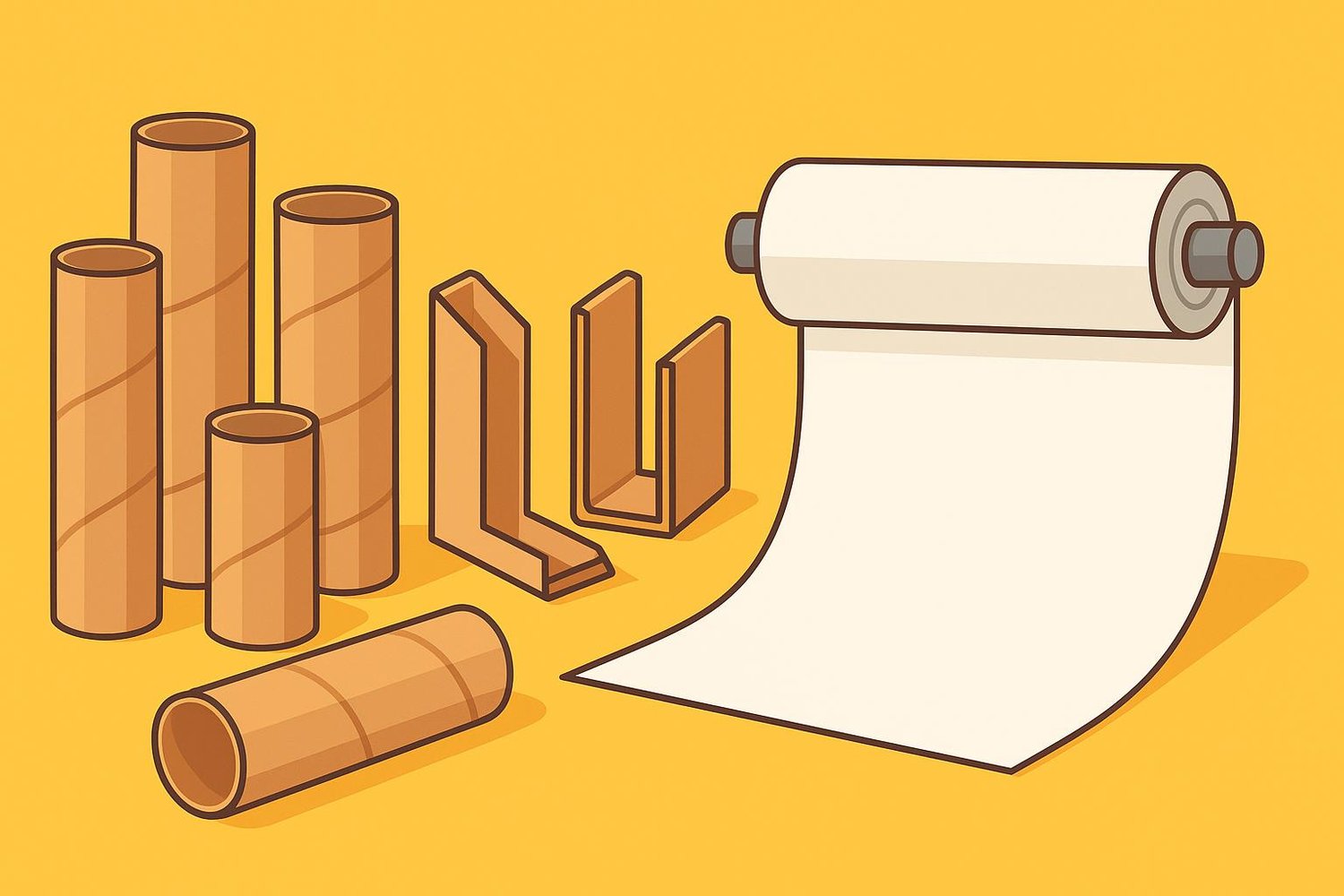

The Advantages of Using Polished Paper Cores in Industrial Applications

In various manufacturing sectors, the performance of machinery often depends on the quality of even the smallest components. One such component is the paper core used for winding materials like films, textiles, and foils. Among the different types available, polished paper cores have gained popularity for their superior finish and enhanced usability.

Polished paper cores are treated to achieve a smooth and refined surface. This finish isn’t merely for aesthetics—it reduces surface friction, allowing materials to glide evenly without snagging or tearing. In fast-paced production environments, this benefit helps prevent costly delays and ensures consistent quality output. The smooth surface also makes it easier to apply and remove materials, saving time during roll changes.

The Polished Paper Core excels in applications where cleanliness and appearance are important. Its sleek finish reduces dust and debris, which is especially valuable in industries such as food packaging, medical supplies, and electronics, where contamination must be minimized. This added cleanliness helps maintain hygiene standards and product integrity.

Another key advantage is the durability offered by polished paper cores. Despite their refined look, these cores are built for strength. They resist crushing and maintain shape under significant pressure, even during high-speed winding. Manufacturers can also customize them based on specific needs, selecting core thickness, diameter, and length to suit their machinery and product requirements.

Incorporating polished paper cores into a production process is a smart move for businesses focused on efficiency and presentation. They offer an ideal balance of strength, smooth performance, and visual appeal, contributing to improved operational flow and customer satisfaction. As industries continue to push for quality and precision, polished paper cores remain a trusted choice for dependable performance.