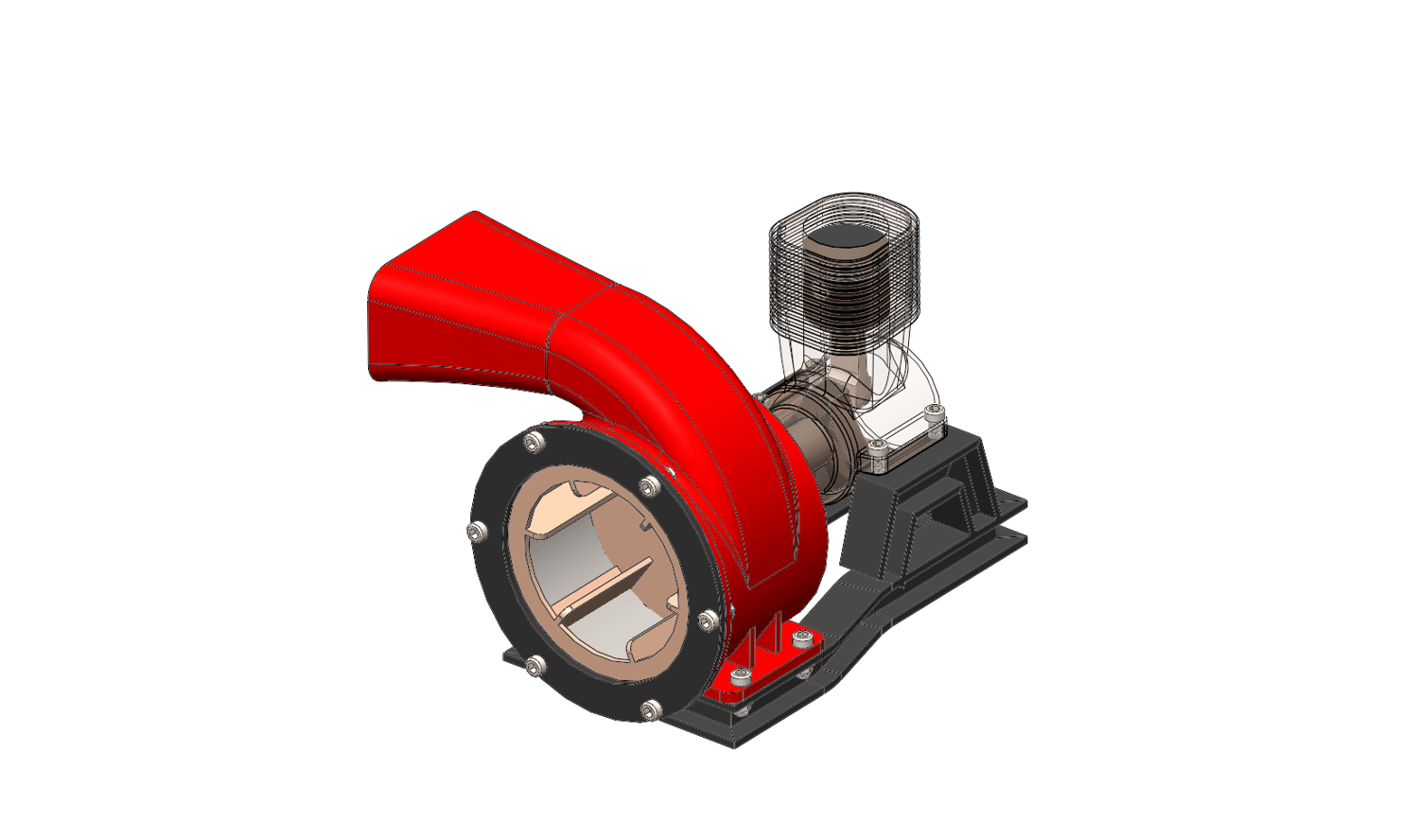

SolidWorks Tutorial: Industrial Circulator Gas Fan | Design, Assembly & Motion Study

🔧 SolidWorks Tutorial: Design, Assembly & Motion Study of a Circulator Fan

What You'll Learn in This Video:

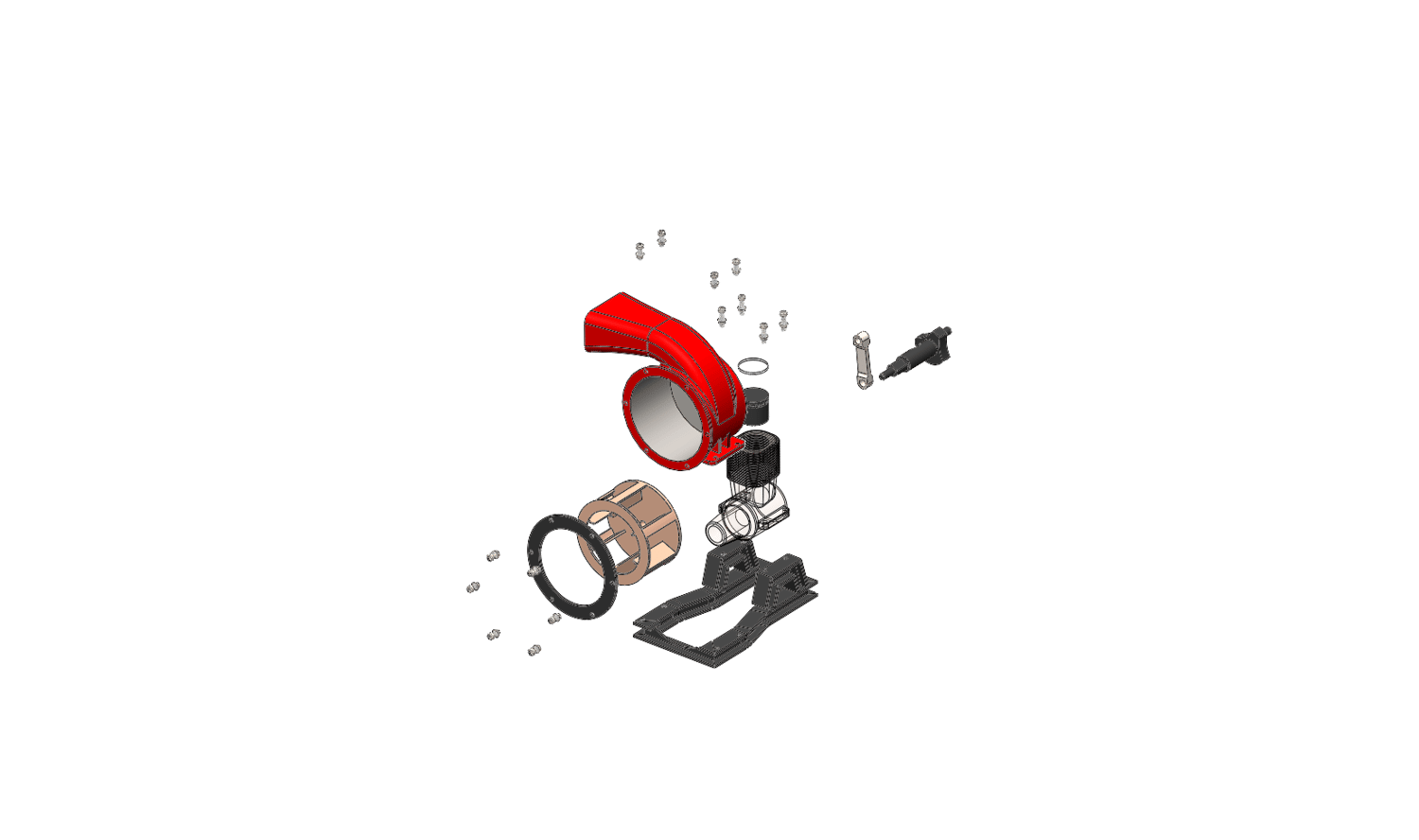

- Component Breakdown and Design: Detailed steps to model each component of the circulator fan, including the impeller housing, gasket, impeller, engine block, piston, piston pin, seals, connecting rod, crankshaft, bolts, washers, nuts, and base.

- Assembly Techniques: How to assemble all parts accurately, ensuring proper alignment and functionality.

- Motion Study: Conducting a motion analysis to verify the performance and efficiency of the circulator fan.

- Optimization and Validation: Tips to optimize your design for performance, durability, and manufacturability.

Why This Tutorial?

Designing and assembling a circulator fan in SolidWorks provides a hands-on understanding of mechanical systems and component interactions. Conducting a motion study helps you verify the dynamic performance of your design, preparing you for more advanced engineering challenges.

Key Features Covered:

Detailed 3D modeling of each component

Assembly of the circulator fan with precise mating

Applying motion constraints and conducting motion analysis

Optimization tips for improved performance and efficiency

Validation using SolidWorks simulation tools

By the end of this tutorial, you'll have mastered the skills to design, assemble, and analyze a complete circulator fan, significantly boosting your CAD proficiency and mechanical design expertise.