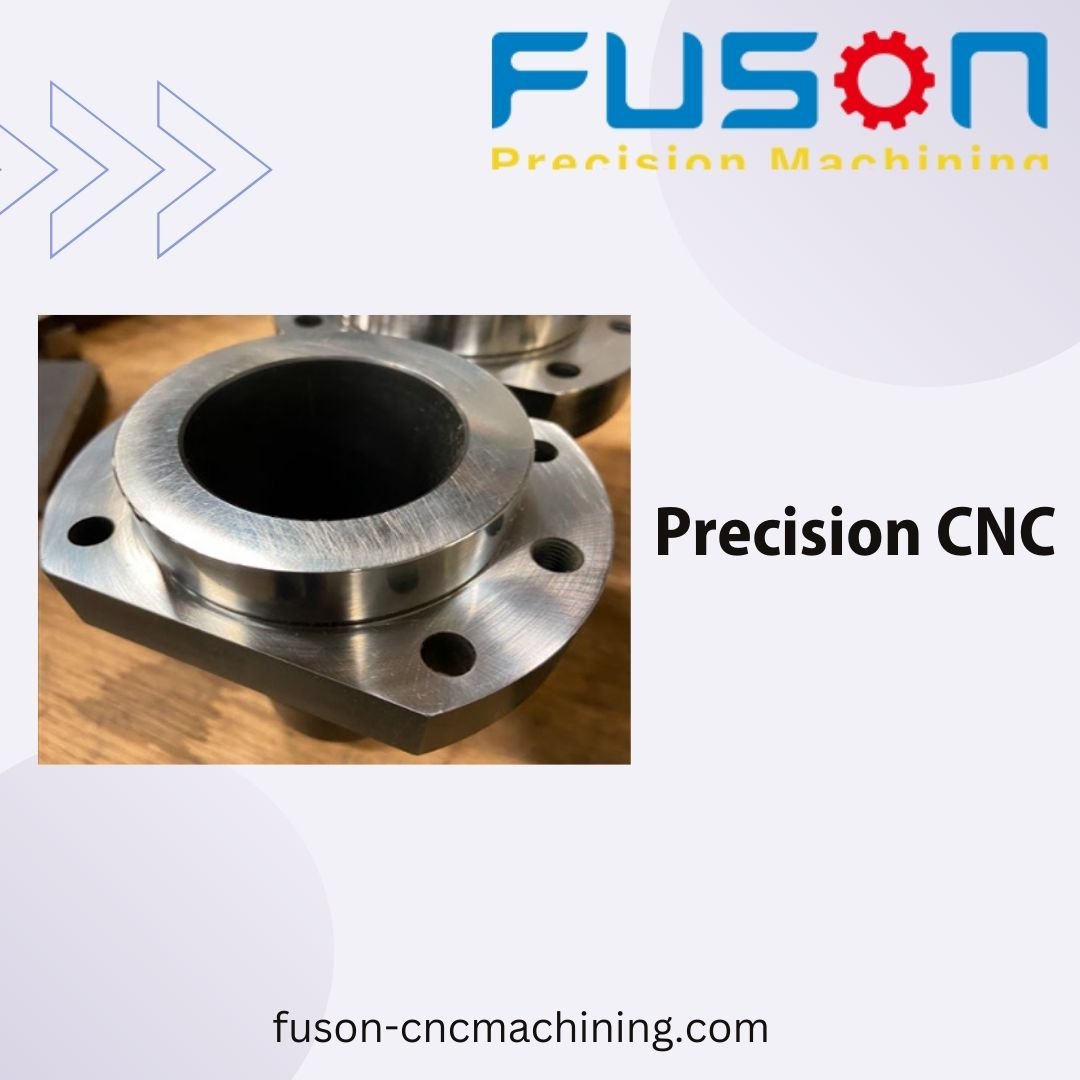

The Art of Precision: Exploring the World of CNC Machining

Precision CNC machining services have transformed the industrial sector by allowing companies to make intricate and precise parts quickly and accurately. But what is precisely and how does precision CNC machining operate? We'll go into the process behind precision CNC machining in this blog post as well as examine some of its many uses. Discover the vast array of opportunities that come with precision CNC machining by reading on, whether you're a business owner or just interested in contemporary manufacturing methods.

What does precision CNC milling entail?

Precision In order to create high-precision parts and components, a manufacturing method known as CNC machining uses computer-controlled equipment. The term "CNC" stands for "computer numerical control," which refers to the programming of a machine's movements using numerical code entered into a computer.

The capacity to precisely repeat procedures with little to no human involvement is precision CNC machining's main advantage over conventional manual methods. This makes it the perfect option for creating intricate shapes and complex designs that demand a high degree of accuracy and consistency.

Speed is a key advantage of this technology in addition to precision. Once correctly configured, these robots can operate continuously without hiccups or mistakes, delivering massive volumes of goods quickly.

Precision CNC machining has considerably increased production productivity by lowering labor costs and enhancing product consistency and quality. We may anticipate even more creative uses of this technique in a variety of industries in the coming years as a result of ongoing technological improvements.

Knowing the Techniques and Potential of CNC Machining

Precision The production of high-quality parts and components is done using the robust manufacturing technique known as CNC machining. But what precisely does CNC machining entail? In essence, it entails the use of sophisticated computer software to direct the motion of cutting instruments in order to mold raw materials into complex shapes.

Round items like shafts or cylinders are frequently made using the precision machining technique known as CNC turning. The workpiece rotates as a cutting tool trims away extra material until the desired form is obtained. Tight tolerances and extremely exact measurements are the outcome.

Contrarily, CNC milling makes use of several cutters mounted on revolving spindles to remove material from a still workpiece. This enables the creation of intricate structures and geometries from solid metal or plastic components. This technique also allows for the speedy production of prototypes without compromising precision.

Knowing the capabilities of these processes enables the maintenance of high quality standards at less expensive costs than conventional approaches, while ensuring smooth production runs with less waste. We may anticipate Precision CNC Machining transforming contemporary manufacturing practices in far more inventive ways as technology keeps developing quickly!

Investigating the Various Uses of Precision CNC Machining Services

Are you seeking for parts that are exact and of a high caliber to use in your projects? Precision CNC machining services are your best option. Precision CNC machining is a game-changer in the manufacturing sector because it enables the production of functioning prototypes and end-use products with enhanced tolerances and features. We'll look at the various uses for precision CNC machining services in this post, along with how they can help your company. So take a seat, unwind, and let's explore the realm of precise engineering!

Functional prototypes and end-use parts using precision CNC machining

Precision Producing functioning prototypes and finished products using CNC machining services is a fantastic choice. From aircraft to medical equipment, these components can be employed in a range of fields. Precision provided by CNC machines enables the production of extremely accurate parts that adhere to exact specifications.

Producing numerous design iterations fast is one advantage of using precise CNC machining for functional prototypes. As a result, engineers and designers can test alternative concepts and make any necessary adjustments before the product is finished. As adjustments may be made earlier in the process, it also aids in reducing manufacturing time and costs.

Precision CNC machining delivers more accuracy and consistency for end-use products than conventional manufacturing processes like injection molding or casting. Because of this, finished items are of greater quality and have fewer mistakes or flaws.

Additionally, there are countless opportunities for customization when designing practical prototypes or final components because numerous materials, including metals, plastics, and composites, may be machined using CNC technology.

Tight fits between components are made possible by the precise tolerances obtained by precision CNC machining, which enhances overall functionality and lessens wear on individual parts over time.

When looking to manufacture high-quality end-use components or functional prototypes with amazing accuracy and efficiency, using precision Precision CNC Machining Services is a great option.