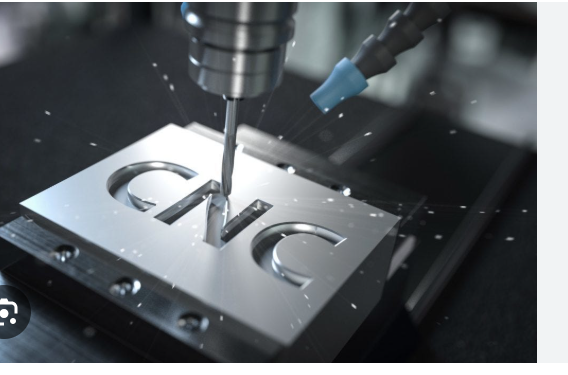

Introduction to CNC Milling Machine

The cnc milling machine has transformed the way industries manufacture precision components. By combining automation with computer numerical control, manufacturers can achieve high-quality output with consistent accuracy. From aerospace to automotive and electronics, these machines have become integral to modern production processes.

Basic Working Principle

A cnc milling machine operates by following pre-programmed instructions from CAD and CAM software. The software generates G-code, which directs the machine’s cutting tools to remove material along specific paths. This precise control enables the production of complex shapes and intricate designs that are difficult to achieve manually.

Types of CNC Milling Machines

Vertical Milling Machines

Vertical machines have a spindle that moves vertically. These are suitable for drilling, engraving, and surface milling. Their versatility makes them ideal for small- to medium-scale manufacturing.

Horizontal Milling Machines

Horizontal machines have a spindle oriented horizontally, making them suitable for heavy-duty material removal and slot cutting. They are often preferred for large and complex components.

5-Axis Milling Machines

5-axis cnc milling machines can move a cutting tool along five different axes simultaneously. This allows the machining of complex components in a single setup, improving efficiency and reducing errors.

Benefits of Using CNC Milling Machines

Precision and Accuracy

CNC milling machines are capable of producing parts with tight tolerances. This precision is crucial in industries like aerospace and medical device manufacturing.

Consistent Production

Once programmed, the machine produces identical parts repeatedly, ensuring uniformity and reducing human error in production.

Time Efficiency

Automation speeds up manufacturing processes. Multiple CNC milling machine operations can be completed faster compared to manual machining, which saves time and reduces labor costs.

Complex Design Capability

CNC technology allows for intricate designs, including curved surfaces, deep pockets, and threaded components. Such precision is challenging to achieve with manual tools.

Materials Machined by CNC Milling Machines

CNC milling machines are compatible with a wide range of materials. Commonly machined metals include aluminum, stainless steel, titanium, and brass. Plastics and composite materials are also widely processed, depending on the application requirements.

Industry Applications

Automotive Industry

Automotive manufacturers use cnc milling machines to produce engine components, transmission parts, and other precision parts. Accurate machining ensures the performance and reliability of vehicles.

Aerospace Sector

The aerospace industry relies on cnc milling machines for turbine blades, structural components, and landing gear. Precision and reliability are critical in this sector.

Electronics Manufacturing

Enclosures, heat sinks, and mechanical assemblies for electronic devices are efficiently produced using cnc milling machines, contributing to product functionality and durability.

Medical Field

Surgical instruments, prosthetic components, and implants require high precision. CNC milling machines help meet these stringent requirements by providing smooth finishes and exact dimensions.

Selecting the Right CNC Milling Machine

Machine Specifications

Important factors include spindle speed, axis configuration, and work area dimensions. The choice depends on the complexity and size of the components being manufactured.

Software Integration

Compatibility with CAD and CAM software is essential for translating designs into precise machining instructions. Proper integration ensures efficient production workflows.

Supplier Support

A reliable supplier provides installation support, training, and maintenance services, ensuring long-term performance of the machine.

Tooling and Maintenance

Using the correct cutting tools and following maintenance schedules ensures consistent quality and prolongs the life of the cnc milling machine.

Current Trends

Robotic Integration

Integrating robotics with cnc milling machines enhances productivity, reduces manual intervention, and ensures consistent output quality.

Multi-Material Machining

Advanced machines can handle different materials in a single operation, increasing flexibility and reducing assembly time.

Digital Twin Technology

Virtual simulations of the milling process help identify potential issues before production, minimizing errors and optimizing operations.

Sustainability

Energy-efficient machines and optimized material usage support environmentally responsible manufacturing practices.

Challenges in CNC Milling

Initial Investment

CNC milling machines require significant upfront investment. However, the long-term benefits in precision, efficiency, and reduced labor often outweigh the costs.

Skilled Workforce

Operators need specialized training to program and operate these machines effectively. Skilled personnel are essential for maximizing machine potential.

Complexity of Advanced Components

Highly intricate designs require advanced programming and precise machining strategies, making expertise and proper planning necessary.

Conclusion

CNC milling machines are indispensable in modern manufacturing, offering precision, efficiency, and versatility. From automotive to medical applications, these machines ensure high-quality, consistent output. Continued advancements in technology, including multi-axis machining, automation, and digital simulations, will further enhance the capabilities of cnc milling machines, allowing industries to meet complex design requirements and maintain competitive advantages.