Great hardware isn’t just designed—it’s manufactured on time, to spec, and at a price that still makes sense when volume grows. The shortest path from CAD to a dependable supply is partnering with a CNC shop that behaves like an extension of engineering: multi-axis capability, material fluency from aluminum to advanced ceramics, disciplined metrology, and a calm logistics routine. This playbook distills how to brief, validate, and scale with a modern machining partner so prototypes predict production and ramp-ups feel uneventful.

What a True One-Stop CNC Partner Looks Like

A credible “one-stop” isn’t a long machine list; it’s a connected workflow that removes hand-offs and guesswork.

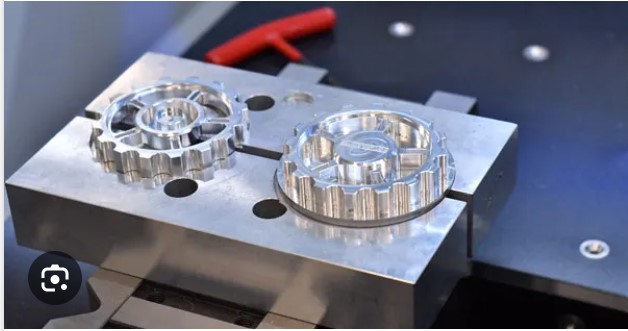

- Core subtractive processes: Multi-axis milling and turning for prismatic and rotational parts, supported by boring and grinding for tight fits and flatness.

- Complexity enablers: Five-axis strategies that minimize setups and tolerance stacking; deep-hole drilling for long, straight bores; vertical honing for roundness and seal-friendly finishes; surface grinding for plate flatness.

- Large-format precision: Gantry and big-envelope machines, plus rigid, modular fixturing that survives the entire journey from roughing and stress relief to finishing.

- Finishes and treatments under control: Heat-treat sequencing that anticipates growth, consistent bead-blast aesthetics, anodizing/passivation/plating with clear masking plans, and post-finish sizing when critical fits demand it.

- Light assembly and tooling: Fixture co-design and sub-assemblies so the first article is a rehearsal for production, not a one-off showpiece.

The telltale sign is orchestration: CAM, fixturing, inspection, and finishing evolve together with documented change control.

Five-Axis and Deep-Hole Drilling: Process Tools, Not Buzzwords

Five-axis is a tolerance instrument. Fewer re-clamps mean less stack-up error, better positional accuracy across related features, and cleaner surfaces on complex geometry. Approaching angled pockets, undercuts, impellers, and intersecting bores from the correct orientation also shortens programs and reduces manual blending.

Deep-hole drilling is how long bores stay honest. With the right pilot strategy, coolant delivery, and chip evacuation, the bore holds axis and thermal stability. Follow with vertical honing to lock cylindricity, roundness, and micro-finish. Hydraulic manifolds, pump housings, actuator bodies, and precision https://www.sppcncmachining.com shafts all live or die on these details.

Material Fluency: Personalities, Not Just Properties

A shop that anticipates failure modes before they happen is worth its weight in carbide. Expect practical mastery across:

- Aluminum (2xxx/6xxx/7xxx): Speed and thermal conductivity. The real craft is burr control, plate flatness, and cosmetic management before and after finishing.

- Carbon and alloy steels: Economical strength with a habit of moving after heavy roughing. The cure is rough-relieve-finish sequencing and intelligent cleanup stock.

- Stainless steels (304/316/17-4PH): Corrosion resistance with work-hardening risks. Keep tools sharp, parameters assertive, and coolant consistent to avoid rubbing and poor finishes.

- Titanium (Grade 5/23): Fatigue strength and biocompatibility with heat sensitivity. Stable, confident cuts beat timid passes that kill tools and surfaces.

- Copper alloys: Gummy yet brilliant for thermal/electrical parts. High-rake tooling and crisp chip control deliver bright finishes and true dimensions.

- Tungsten carbide and technical ceramics: Usually a world of grinding, superfinishing, and immaculate fixturing. Coolant cleanliness and patient stock removal turn “possible” into “repeatable.”

- Engineering plastics and composites: Low cutting forces, high chatter/melt risk. Use sharp tools, controlled clamping, and post-machining stability checks to prevent creep and edge smear.

The value add is options: equivalent alloys, alternate heat-treats, or smarter coatings that meet function while trimming cost and lead time.

Drawings, Notes, and the Specs Between the Lines

Parts pass or fail on details that drawings often under-specify. Lock these in early:

- Functional datums and GD&T: Fixture parts as they live in the assembly so CMM results mirror reality, not an arbitrary coordinate system.

- Residual stress management: Thin walls and wide plates distort. Plan stress relief between roughing and finishing, and leave stock for a final skim cut.

- Edge policy: Define break edges and deburr standards. Many expensive rejections are actually $0.02 burr problems.

- Coating math: Finishes move dimensions. Agree on target thickness, masking, measurement points, and post-finish sizing where fits are tight.

- Surface integrity beyond Ra: For sealing, wear, or fatigue, specify lay direction, recast removal (after EDM), and micro-geometry—not just an average roughness number.

Document these once and every subsequent PO gets safer.

Prototype Like You Mean to Produce

Treat prototypes as process proofs, not just geometry proofs. Ask your shop to mirror production intent:

- Same fixture concept: Zero-point pallets or modular fixtures that will survive volume, not improvised clamps.

- Stable tool libraries: The cutters you approve now should be the cutters used at scale.

- On-machine probing: Early feedback loops catch drift and seed the future SPC plan.

- Capability snapshots on CTQs: Even with small lots, a quick read on the riskiest dimensions predicts production behavior.

When first articles validate the recipe, ramp-up is a scheduling exercise—not a rescue mission.

Quality You Can Feel in the Routine

Certificates don’t cut metal; disciplined habits do.

- In-process verification: Probing and controlled tool life prevent piles of bad parts.

- CMM envelope and throughput: Enough range to measure large work and enough throughput to avoid inspection bottlenecks.

- SPC where it matters: Data on the handful of features that actually drive fit/function, not noise on irrelevant dimensions.

- MRB discipline: Clear non-conformance handling, concession rules, and corrective actions that flow back into travelers and setup sheets.

- Traceability: Material certs, lot control, and photo-rich travelers that make audits boring.

Ask to see a sample inspection pack; completeness and clarity speak volumes.

Finishing Without Surprises

Finishing isn’t a last step; it’s part of the process plan.

- Sequencing: Heat-treat before finishing; final machining passes after treatments when required.

- Witness coupons: Validate coating thickness and adhesion on coupons before committing a full batch.

- Cosmetics: Agree on bead media, gloss targets, and acceptable variation. Consistent surfaces come from consistent recipes, not wishful thinking.

This forethought is how perfectly machined parts remain perfect after finishing.

Packaging, Freight, and the Hidden Columns of Cost

Piece price is one column. The quieter columns decide success.

- Packaging engineering: Oil wraps, VCI papers, and custom foam prevent transit dings, latent corrosion, and subtle dimensional drift.

- Freight logic: Air for prototypes and design changes; consolidated ocean for stable production. Align incoterms with your risk appetite.

- Queue control: Heat-treat, coating, and CMM time are real bottlenecks. Mature shops schedule them like machines.

- Communication cadence: Weekly snapshots with progress, next operations, and risk flags beat silence every time.

When these “boring” topics are handled well, programs stay calm.

Pitfalls That Kill Programs—and How to Retire Them

- Everything is tight “just in case.”

- Concentrate precision on functional features; standardize and relax the background. Cycle time drops and scrap follows.

- Finishing added at the end.

- Integrate coatings into the cut plan. Decide masking and post-finish sizing before chips fly.

- Prototype magic that won’t scale.

- Use production fixtures, tool libraries, and probing from day one. Lock the process, not just the part.

- Tribal knowledge over documents.

- Setup sheets, travelers, and annotated photos convert heroics into a system. Future changes become predictable.

Copy-Paste RFQ Skeleton That Gets Better Quotes

Attachments

- STEP model and fully dimensioned PDF with GD&T

- Material spec plus any acceptable alternates

- Finish/coating callouts, thickness targets, masking plan

- Edge-break/deburr and cosmetic standards (photos if available)

Priorities

- List of CTQs and capability expectations (where applicable)

- Noncritical dimensions where standard tolerances are fine

- Expected volumes and ramp cadence (prototype → pilot → production)

Process Expectations

- Short outline: setup count, fixture concept, probing, heat-treat order, finishing route

- Confirmation of working envelope and five-axis availability (if geometry hints at it)

- Sample inspection report format and CMM capacity

Logistics

- Packaging standard (VCI/oil/foam density)

- Preferred freight mode and incoterms

- Build report cadence and key contacts

Send this once; quote accuracy and first-article success improve immediately.

The Payoff: Quiet, Repeatable Precision

The best CNC partners combine breadth of process, material mastery, metrology discipline, and respectful communication. They help simplify drawings, shave risk out of cycle time, and ship inspection-ready parts that behave the same on the tenth order as they did on the first. Build your shortlist around those signals and your supply chain will feel refreshingly uneventful—blueprint in, certified parts out, schedules intact. That quiet reliability is how prototypes become products and products become a business that scales.