Introduction

In today’s fast-moving digital economy, companies are constantly seeking solutions that enhance accuracy, speed, and operational flow. One important contributor to this efficiency is the development of advanced scanning technology. Modern facilities such as an auto barcode reader factory are at the center of this evolution, supplying industries with reliable tools that simplify tracking, inventory, and data management. These devices play a crucial role in transforming how products are manufactured, distributed, and managed across the supply chain.

Evolution Of Automated Data Capture

The journey from manual data entry to automated systems has been remarkable. Decades ago, businesses relied heavily on employees manually recording product information. This was time-consuming and prone to human error. The introduction of barcode systems eliminated much of this inefficiency. Today, with the emergence of automated factories producing barcode readers, data capture is faster, more accurate, and fully integrated into digital networks.

Understanding Production Facilities

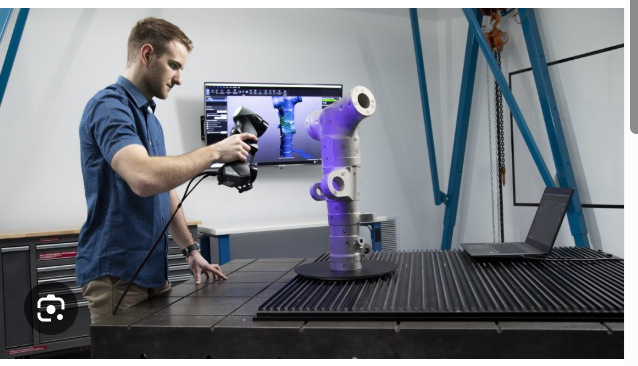

An auto barcode reader factory is designed to create high-performance devices that meet the needs of multiple industries. Such factories combine mechanical engineering, electronics, and software development. The process includes designing durable casings, integrating advanced sensors, and embedding decoding algorithms. These elements ensure that the end products can handle complex scanning requirements in diverse environments.

Importance In Retail And E-Commerce

Retailers rely heavily on fast scanning technology. At checkout counters, efficient devices reduce waiting time and enhance customer experience. Warehouses supporting online retailers also benefit by managing large-scale inventories with minimal errors. The technology supplied by these factories allows for accurate order processing and smooth distribution, which is essential in meeting customer expectations in the age of e-commerce.

Applications In Logistics And Warehousing

Logistics companies operate in a highly competitive field where precision and speed define success. Barcode readers manufactured in automated factories are used to scan packages on conveyor belts, track shipments, and confirm delivery statuses. By removing the need for manual checks, businesses can streamline operations, minimize delays, and maintain transparent tracking systems.

Role In Healthcare And Safety

The healthcare industry has strict requirements when it comes to accuracy. Auto barcode readers are used to confirm patient records, track medical supplies, and manage pharmaceuticals. A reliable device ensures that the correct medication reaches the right patient, which directly impacts patient safety. The factories behind these devices are therefore contributing indirectly to saving lives by improving operational precision.

Enhancing Manufacturing Lines

Factories producing goods also require constant monitoring of raw materials and finished products. Automated scanners detect and record items in real time, allowing managers to maintain production flow without disruptions. They can quickly identify shortages, defective items, or delays. The scanners supplied by specialized production facilities enable manufacturing companies to uphold consistent quality and reduce waste.

Integration With Digital Systems

Modern scanning technology is not limited to reading codes; it also connects with broader digital ecosystems. Barcode readers manufactured in specialized facilities are designed to integrate with inventory management software, enterprise auto barcode reader factory resource planning platforms, and cloud-based databases. This ensures that businesses can track products across the entire supply chain with real-time visibility.

Cost Benefits For Businesses

While the initial investment in automated scanning systems may seem significant, the long-term benefits outweigh the costs. Devices from a reliable auto barcode reader factory reduce labor expenses, prevent costly errors, and accelerate processes. Businesses gain higher productivity and customer satisfaction, resulting in greater profitability over time.

Technological Advancements In Production

The future of barcode reader manufacturing involves integrating artificial intelligence and machine learning. Devices are expected to become smarter, capable of reading damaged codes, and even identifying multiple formats simultaneously. Production facilities are focusing on building adaptable devices that can serve industries with evolving needs, ensuring they remain relevant in a rapidly changing market.

Contribution To Global Trade

Global trade depends on accurate documentation and tracking. Barcode readers supplied by advanced factories are essential for international logistics companies that manage shipments across borders. From customs clearance to last-mile delivery, these devices ensure transparency and trust in global business transactions.

Conclusion

The presence of an auto barcode reader factory is more than just about producing scanning devices; it represents a vital part of modern business infrastructure. These factories supply industries with the tools necessary to streamline operations, enhance accuracy, and improve customer satisfaction. As technology continues to evolve, their role will only grow more significant, ensuring that businesses remain competitive in a fast-paced, globalized world.