As technology continues to evolve, precision and customization have become the cornerstones of modern healthcare. One of the driving forces behind this transformation is medical CNC machining, a process that has changed how medical devices and components are produced. From surgical instruments to complex implants, CNC machining allows manufacturers to meet the highest standards of quality, accuracy, and reliability required in the healthcare sector.

In this article, we explore how medical CNC machining is revolutionizing the production of healthcare equipment, the types of materials it works with, its diverse applications, and the reasons why it’s become a trusted solution in the medical industry.

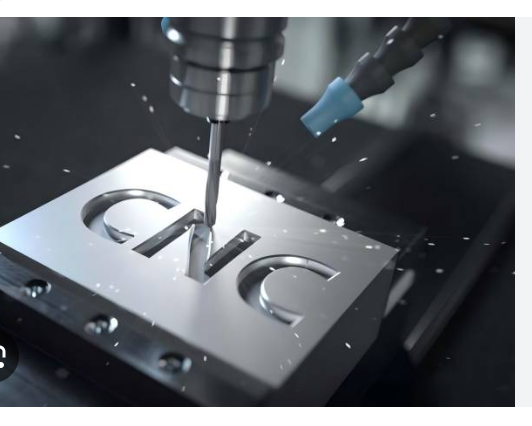

What Is Medical CNC Machining?

Medical CNC machining refers to the use of computer-controlled machines to create highly accurate components used in medical applications. CNC stands for Computer Numerical Control, a system that translates digital designs into exact physical parts by removing material from a workpiece using precision tools.

This subtractive manufacturing process is used to create components that require tight tolerances, intricate shapes, and flawless finishes. In the medical field, where precision can mean the difference between life and death, CNC machining is often the preferred production method.

Why CNC Machining Is Essential in Healthcare

Healthcare products must not only perform reliably but must also comply with strict regulations to ensure safety and effectiveness. Here’s why medical CNC machining is vital:

- Accuracy: It allows for micrometer-level precision, ensuring parts fit perfectly with human anatomy or other devices.

- Repeatability: Every part produced is identical to the last, which is essential for surgical instruments and implants.

- Flexibility: CNC machining works with a variety of materials and can handle complex geometries.

- Scalability: It supports both small-scale prototyping and high-volume production with consistent quality.

Common Materials Used in Medical CNC Machining

Materials used in medical CNC machining must meet high standards for durability, safety, and biocompatibility. Commonly used materials include:

1. Titanium

Widely used for orthopedic implants and dental posts due to its strength, light weight, and resistance to corrosion. Titanium is also biocompatible, making it safe for long-term use inside the human body.

2. Stainless Steel

Ideal for surgical tools and instrument parts, stainless steel is durable, corrosion-resistant, and easily sterilized.

3. PEEK (Polyetheretherketone)

A strong, heat-resistant thermoplastic used in spinal cages and orthopedic implants. It mimics the flexibility of human bone, making it ideal for medical applications.

4. Medical-Grade Plastics

Materials such as PTFE, UHMW-PE, and Delrin are commonly used for disposable devices, housings, and components that require sterilization.

5. Aluminum

Though not typically used in implants, aluminum is widely used in medical device housings and lightweight structural parts due to its machinability and cost-efficiency.

Applications of Medical CNC Machining

CNC machining supports a broad range of healthcare applications, including:

• Surgical Instruments

Scalpels, forceps, clamps, and retractors are machined to precise dimensions to ensure accuracy and reliability during procedures. Smooth, burr-free finishes are crucial to prevent tissue damage or contamination.

• Orthopedic and Dental Implants

Hip joints, spinal implants, dental crowns, and screws are manufactured to exact specifications. Custom implants tailored to individual patients can also be machined using digital imaging and modeling data.

• Prosthetics

CNC machining creates custom sockets and connectors that provide a comfortable fit for patients, enhancing the usability and performance of prosthetic limbs.

• Diagnostic Equipment

Internal and external components of diagnostic tools—such as MRI, CT scan, and ultrasound machines—are made using CNC machining for precision and durability.

• Catheters and Endoscopic Components

Micro-CNC machines can produce small, delicate parts required for minimally invasive surgical tools and diagnostic instruments.

Benefits of Medical CNC Machining

✅ High Precision and Tolerances

Tight tolerances as low as ±0.001 mm are achievable, making it ideal for producing tiny, intricate parts with exact measurements.

✅ Rapid Prototyping

CNC machining allows for fast prototyping of medical devices, helping engineers and designers test functionality, fit, and aesthetics before full-scale production.

✅ Customization

Many medical devices must be tailored to individual patients. CNC machining allows for the customization of implants and prosthetics without extensive retooling.

✅ Compliance with Medical Standards

Manufacturers can meet regulatory requirements like ISO 13485 and FDA standards through strict process controls and traceability provided by CNC machining.

✅ Surface Finish Control

Medical devices often require ultra-smooth surfaces to minimize bacterial growth and support sterilization. CNC machining can produce mirror-like finishes where needed.

CNC Machining in Medical Device Prototyping

Speed and adaptability are essential in developing new medical technologies. Medical CNC machining provides a streamlined path from concept to prototype, offering:

- Fast Turnaround Times: Engineers can quickly test and revise designs.

- Real-World Testing: Machined prototypes made with final materials provide realistic testing conditions.

- Reduced Costs: CNC machining eliminates the need for expensive molds or tooling.

This makes it a preferred choice for startups, research institutions, and medical device developers who need to iterate quickly and cost-effectively.

Challenges in Medical CNC Machining and How They Are Addressed

Challenge

Solution

Material hardness (e.g., titanium)

Use of advanced carbide tools and optimized speeds/feeds

Tight tolerance demands

Precision equipment with closed-loop control and quality checks

Micro part fabrication

Specialized tools and micro-CNC machines

Surface finish requirements

Secondary polishing, deburring, or electropolishing processes

Professional CNC machining companies often have the tools, skills, and certifications required to meet these challenges head-on.

Future Trends in Medical CNC Machining

The future of medical CNC machining looks promising, with advancements in both materials and technology. Key trends include:

• AI-Enhanced Machining

Artificial intelligence is being used to monitor cutting tools, adjust machining parameters in real-time, and predict machine maintenance—reducing downtime and improving quality.

• Miniaturization

As medical devices become smaller, CNC machines are evolving to produce micro-scale components with incredible accuracy.

• Integration with Additive Manufacturing

Combining CNC machining with 3D printing (hybrid manufacturing) opens new possibilities in medical product development.

• Robotics and Automation

Fully automated CNC machining centers are increasing production capacity and consistency, especially for high-volume medical parts.

Conclusion

The importance of medical CNC machining in the healthcare industry cannot be overstated. Its ability to produce safe, precise, and customizable medical components is transforming how doctors treat patients and how companies bring medical innovations to life. Whether it’s creating the next generation of implants or enabling rapid prototyping of surgical tools, CNC machining remains a cornerstone of modern medical manufacturing.

As healthcare needs continue to grow and evolve, CNC machining will remain essential in ensuring that medical devices are built with accuracy, reliability, and care—ultimately contributing to better outcomes for patients worldwide.