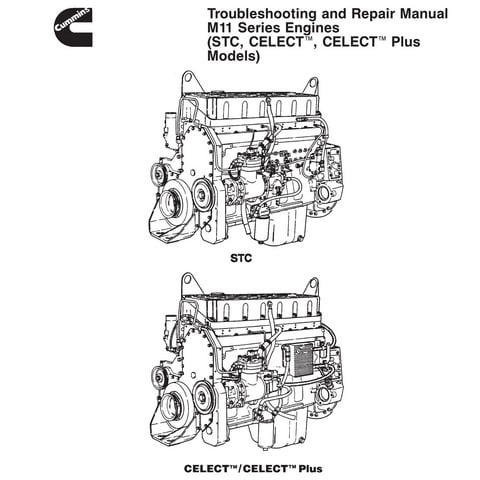

Cummins M11 Series Engines Troubleshooting and Repair Manual

-

This complete service repair workshop manual PDF download for the Cummins M11 Series Engines (STC, CELECT™, CELECT™ Plus Models) has easy-to-read text sections with top quality diagrams, pictures and illustrations. The step by step instructions show you how to fault find or complete any repair or overhaul, correctly and efficiently, saving time and avoiding costly mistakes.

This manual provides instructions for troubleshooting and repairing this engine in the chassis.

TABLE OF CONTENTS :

Introduction

Engine Identification

Troubleshooting Symptoms

Complete Engine — Group 00

Cylinder Block — Group 01

Cylinder Head — Group 02

Rocker Levers — Group 03

Cam Followers/Tappets — Group 04

Fuel System — Group 05

Injectors and Fuel Lines — Group 06

Lubricating Oil System — Group 07

Cooling System — Group 08

Drive Units — Group 09

Air Intake System — Group 10

Exhaust System — Group 11

Compressed Air System — Group 12

Electrical Equipment — Group 13

Engine Testing — Group 14

Mounting Adaptations — Group 16

Miscellaneous Hardware — Group 17

Vehicle Braking — Group 20

Service Literature

Component Manufacturers

Specifications

Index

MANUAL SPECIFICATION :

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bulletin No. : 3666139–00

Total Pages : 926

This (OEM) manual pdf download has detailed illustrations as well as step by step instructions, It is 100 percents complete and intact. they are specifically written for the do-it-yourself-er as well as the experienced mechanic. With step by step instruction & highly detailed exploded pictures & diagrams to show you how to complete the required job correctly & efficiently Using. Provides step-by-step instructions based on the complete dis-assembly of the machine. It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. Complete download comes in pdf format which can work under all PC based windows operating system and Mac also, All pages are printable. Using this repair manual is an inexpensive way to keep your vehicle working properly.

This service repair workshop manual PDF download has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This is a must for the Do-It-Yourselfer! Saving Yourself $$$$$$ In Service Repair And Maintenance Costs !!!!

This service repair workshop manual PDF download contains specs, diagrams, actual real photo illustrations, and schemes. In addition to space savings, nice thing about having completly searcheble PDF files instead of a hard-printed manual is that you can use the Search feature in your PDF reader software (Adobe Acrobat) to find just what your looking for and just print out the exact pages you need or all manual easily. This is the same Repair Service manual your local dealer will use when doing a repair.

Instant Download means there is NO shipping costs or waiting for a CD or paper manual to arrive in the mail!, You will receive this manual TODAY via Instant Download on completion of payment via our secure payment processor. We accept ALL major credit/debit cards/paypal.

More Info : https://www.sitelux.com

-

MAIN MENU

COVER PAGE

TABLE OF CONTENTS

INTRODUCTION

ABOUT THIS MANUAL

ACRONYMS AND ABBREVIATIONS

GENERAL CLEANING INSTRUCTIONS

GLASS OR PLASTIC BEAD CLEANING

SOLVENT AND ACID CLEANING

STEAM CLEANING

GENERAL REPAIR INSTRUCTIONS

WELDING ON A VEHICLE WITH AND ELECTRONIC CONTROLLED FUEL SYSTEM

GENERAL SAFETY INSTRUCTIONS

IMPORTANT SAFETY NOTICE

HOW TO USE THE MANUAL

ILLUSTRATIONS

SYMBOLS

ENGINE IDENTIFICATION

ENGINE DIAGRAMS

ENGINE IDENTIFICATION

CUMMINS ENGINE NOMENCLATURE

ECM DATAPLATE

ENGINE DATAPLATE

FUEL PUMP DATAPLATE

SPECIFICATIONS

AIR INTAKE SYSTEM

BATTERIES (SPECIFIC GRAVITY)

COOLING SYSTEM

ELECTRICAL SYSTEM

EXHAUST SYSTEM

FUEL SYSTEM

GENERAL SPECIFICATIONS

LUBRICATING OIL SYSTEM

TROUBLESHOOTING SYMPTOMS

PROCEDURES AND TECHNIQUES

TROUBLESHOOTING SYMPTOMS CHARTS

AIR COMPRESSOR AIR PRESSURE RISES SLOWLY

AIR COMPRESSOR CYCLES FREQUENTLY

AIR COMPRESSOR NOISE IS EXCESSIVE

AIR COMPRESSOR PUMPING EXCESS LUBRICATING OIL INTO THE AIR SYSTEM

AIR COMPRESSOR WILL NOT MAINTAIN ADEQUATE AIR PRESSURE (NOT PUMPING CONTINUOUSLY)

AIR COMPRESSOR WILL NOT PUMP AIR

AIR COMPRESSOR WILL NOT STOP PUMPING

ALTERNATOR NOT CHARGING OR INSUFFICIENT CHARGING

ALTERNATOR OVERCHARGING

COMMUNICATION ERROR - ELECTRONIC SERVICE TOOL OR CONTROL DEVICE

CONNECTING ROD BEARING NOISE

COOLANT IN THE LUBRICATING OIL

COOLANT LOSS (EXTERNAL)

COOLANT LOSS - INTERNAL

COOLANT TEMPERATURE ABOVE NORMAL - GRADUAL OVERHEAT

COOLANT TEMPERATURE IS ABOVE NORMAL - SUDDEN OVERHEAT

COOLANT TEMPERATURE IS BELOW NORMAL

CRANKCASE GASES (BLOWBY) EXCESSIVE

CRANKING FUEL PRESSURE IS LOW

DRIVEABLITY - GENERAL INFORMATION

DRIVEABLITY /LOW POWER - CUSTOMER COMPLAINT FORM

DRIVEABILITY/LOW POWER/EXCESSIVE FUEL CONSUMPTION - CHECKLIST

ENGINE ACCELERATION OR RESPONSE POOR

ENGINE BRAKE DOES NOT OPERATE (CELECT OR CELECT PLUS)

ENGINE BRAKE - LOW RETARDING POWER OR SLOW TO ACTIVATE (CELECT OR CELECT PLUS)

ENGINE BRAKE - ONE OR MORE CYLINDERS BRAKING WITH POWER SWITCH OFF (CELECT OR CELECT PLUS)

ENGINE DECELERATES SLOWLY (CELECT AND CELECT PLUS)

ENGINE DECELERATES SLOWLY (PT)

ENGINE DIFFICULT TO START OR WILL NOT START (EXHAUST SMOKE)

ENGINE DIFFICULT TO START OR WILL NOT START (NO EXHAUST SMOKE)

ENGINE NOISE DIAGNOSTIC PROCEDURES - GENERAL INFORMATION

ENGINE NOISE EXCESSIVE

ENGINE NOISE EXCESSIVE - COMBUSTION KNOCKS

ENGINE NOISE EXCESSIVE - CONNECTING ROD

ENGINE NOISE EXCESSIVE - MAIN BEARING

ENGINE NOISE EXCESSIVE - PISTON

ENGINE NOISE EXCESSIVE - TURBOCHARGER

ENGINE POWER OUTPUT LOW (CELECT OR CELECT PLUS)

ENGINE POWER OUTPUT LOW (PT)

ENGINE RUNS ROUGH AT IDLE

ENGINE RUNS ROUGH OR MISFIRES

ENGINE SHUTS OFF UNEXPECTEDLY OR DIES DURING DECELERATION

ENGINE SPEED SURGES AT LOW OR HIGH IDLE

ENGINE SPEED SURGES UNDER LOAD OR IN OPERATING RANGE

ENGINE STARTS BUT WILL NOT KEEP RUNNING

ENGINE VIBRATION EXCESSIVE

ENGINE WILL NOT CRANK OR CRANKS SLOWLY (AIR STARTER)

ENGINE WILL NOT CRANK OR CRANKS SLOWLY (ELECTRIC STARTER)

ENGINE WILL NOT SHUT OFF

FUEL CONSUMPTION EXCESSIVE (CELECT AND CELECT PLUS)

FUEL CONSUMPTION EXCESSIVE (PT)

FUEL CONSUMPTION - CUSTOMER COMPLAINT FORM

FUEL CONSUMPTION - GENERAL INFORMATION

FUEL IN THE COOLANT

FUEL IN THE LUBRICATING OIL

INTAKE MANIFOLD AIR TEMPERATURE ABOVE SPECIFICATION

INTAKE MANIFOLD PRESSURE (BOOST) IS BELOW NORMAL

LOW IDLE ADJUST SWITCH DOES NOT WORK

LUBRICATING OIL CONSUMPTION EXCESSIVE

LUBRICATING OIL CONTAMINATED

LUBRICATING OIL IN THE FUEL

LUBRICATING OIL PRESSURE HIGH

LUBRICATING OIL PRESSURE LOW

LUBRICATING OIL SLUDGE IN THE CRANKCASE EXCESSIVE

LUBRICATING OIL TEMPERATURE ABOVE SPECIFICATION

LUBRICATING OR TRANSMISSION OIL IN THE COOLANT

MAIN BEARING NOISE

OIL CONSUMPTION

OPERATING FUEL PRESSURE IS LOW

PISTON NOISE

RESPONSE TEST - CELECT AND CELECT PLUS

SMOKE, BLACK - EXCESSIVE (CELECT AND CELECT PLUS)

SMOKE, BLACK - EXCESSIVE (PT)

SMOKE, WHITE - EXCESSIVE (CELECT AND CELECT PLUS)

SMOKE, WHITE - EXCESSIVE (PT)

STEP TIMING CONTROL (STC) VALVE IS NOT SHIFTING CORRECTLY

TURBOCHARGER LEAKS ENGINE OIL OR FUELBVARIABLE SPEED (VS) GOVERNOR - FUEL LEAK AT THE THROTTLE SHAFT

VARIABLE SPEED (VS) GOVERNOR - FUEL LEAK AT THE THROTTLE SHAFT

VARIABLE SPEED (VS) GOVERNOR - SPEED IS NOT SET CORRECTLY

VARIABLE SPEED (VS) GOVERNOR - SURGE WITH ENGINE UNDER LOAD

COMPLETE ENGINE - GROUP 00

COMPLETE ENGINE - GENERAL INFORMATION

ENGINE INSTALLATION

INSTALL

ENGINE REMOVAL

REMOVE

SERVICE TOOLS

ENGINE REMOVAL AND INSTALLATION

CYLINDER BLOCK - GROUP 01

ACCESSORY DRIVE SEAL

CLEAN

INSTALL

REMOVE

ALTERNATOR DRIVE SEAL

CLEAN

INSTALL

REMOVE

BEARINGS, CONNECTING ROD

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

BEARINGS, MAIN

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

BEARINGS, THRUST

INSTALL

REMOVE

CAMSHAFT

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

CAMSHAFT BUSHINGS

CLEAN

INSPECT FOR REUSE

INSTALL

NUMBER ONE BUSHING - INSTALLATION

NUMBER SEVEN BUSHING - INSTALLATION

NUMBER SIX THROUGH NUMBER TWO BUSHING - INSTALLATION

REMOVE

CAMSHAFT END CLEARNACE

MEASURE

CAMSHAFT GEAR (CAMSHAFT INSTALLED)

INSPECT FOR REUSE

INSTALL

REMOVE

CAMSHAFT GEAR (CAMSHAFT REMOVED)

INSTALL

REMOVE

CONNECTING ROD

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

CRANKSHAFT

ROTATION CHECK

CRANKSHAFT GEAR, FRONT (CRANKSHAFT INSTALLED)

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

CRANKSHAFT PULLEY

INSPECT FOR REUSE

INSTALL

REMOVE

CRANKSHAFT SEAL, FRONT

CLEAN

INSTALL

REMOVE

CRANKSHAFT SEAL, REAR

CLEAN

INSTALL

REMOVE

CYLINDER BLOCK AND LINER SEATS

LEAK TEST

CYLINDER LINER

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

CYLINDER LINER PROTRUSION

MEASURE

PREPARATORY

GEAR COVER, FRONT

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

GEAR HOUSING, FRONT

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

IDLER GEAR, CAMSHAFT

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

IDLER GEAR, HYDRAULIC PUMP

CLEAN

INSPECT

INSTALL

REMOVE

IDLER GEAR, WATER PUMP

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

PISTON

ASSEMBLE

CLEAN

DISASSEMBLE

GENERAL INFORMATION

INSPECT FOR REUSE

ARTICULATED PISTON

INSTALL

REMOVE

PISTON AND CONNECTING ROD ASSEMBLY

ASSEMBLE

CLEAN

DISASSEMBLE

INSPECT FOR REUSE

INSTALL

REMOVE

PISTON COOLING NOZZLE

INSPECT FOR REUSE

INSTALL

REMOVE

PISTON RINGS

INSPECT FOR REUSE

SERVICE TOOLS

CYLINDER BLOCK

VIBRATION DAMPER

CLEAN

ECCENTRICITY CHECK

INSPECT FOR REUSE

INSTALL

REMOVE

WOBBLE CHECK

WATER HEADER PLATE, CYLINDER BLOCK

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

CYLINDER HEAD - GROUP 02

CYLINDER HEAD

CLEAN

INSPECT FOR REUSE

INSTALL

LEAK TEST

PRESSURE TEST

REMOVE

SERVICE TOOLS

CYLINDER HEAD

ROCKER LEVERS - GROUP 03

CRANKCASE BREATHER (INTERNAL)

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

OVERHEAD SET

ADJUST

ENGINE BRAKE - ADJUST

GENERAL INFORMATION

INJECTOR ADJUSTMENT - CELECT AND CELECT PLUS ENGINES

INJECTOR ADJUSTMENT -STC ENGINES

VALVE ADJUSTMENT - CELECT AND CELECT PLUS ENGINES

VALVE ADJUSTMENT - STC ENGINES

MEASURE

GENERAL INFORMATION

VALVE AND INJECTOR LASH - CELECT AND CELECT PLUS ENGINES

VALVE LASH - STC ENGINES

ROCKER LEVER ASSEMBLY

ASSEMBLE

ALUMINUM SUPPORTS

CAST IRON SUPPORTS

CLEAN

DISASSEMBLE

GENERAL INFORMATION

INSPECT FOR REUSE

INSTALL

REMOVE

ROCKER LEVER COVER

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

ROCKER LEVER HOUSING

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

SERVICE TOOLS

ROCKER LEVERS

CAM FOLLOWERS/TAPPETS - GROUP 04

CAM FOLLOWER ASSEMBLY

ASSEMBLE

CLEAN

DISASSEMBLE

INSPECT FOR REUSE

INSTALL

REMOVE

PUSH RODS OR TUBES

INSPECT FOR REUSE

INSTALL

REMOVE

SERVICE TOOLS

CAM/FOLLOWER/TAPPETS

FUEL SYSTEM - GROUP 05

FLOW DIAGRAM, FUEL SYSTEM

FUEL CONSUMPTION

MEASURE

FUEL FLOW

INITIAL CHECK

LEAK TEST

PRESSURE TEST

MINIMUM CRANKING PRESSURE

MINIMUM OPERATING PRESSURE

FUEL PUMP

CLEAN

INSPECT FOR REUSE

INSTALL

CELECT OR CELECT PLUS

STC

PRIME

CELECT OR CELECT PLUS

GENERAL INFORMATION

STC

REMOVE

CELECT OR CELECT PLUS

STC

ROTATION CHECK

FUEL PUMP GEAR PUMP CHECK VALVE

INSTALL

REMOVE

FUEL PUMP HIGH IDLE SPEED (VS GOVERNOR)

ADJUST

HIGH SPEED

IDLE SPEED

FUEL PUMP IDLE SPEED

ADJUSTMENT

FUEL PUMP PRESSURE REGULATOR

INITIAL CHECK

FUEL PUMP PULSATION DAMPER

INSPECTION FOR REUSE

FUEL PUMP THROTTLE LEVER

ADJUST

FUEL PUMP THROTTLE LINKAGE

ADJUST

FUEL PUMP VS THROTTLE SHAFT HOUSING

INSTALL

REMOVE

FUEL SHUTOFF VALVE (FSOV)

INSPECT FOR REUSE

FUEL SYSTEM - GENERAL INFORMATION

INSTALLATION RECOMMENDATIONS

INSTALLATION PUBLICATIONS

OVERHEAD FUEL TANK REQUIREMENTS

PROPER USE OF FUEL SYSTEM GAUGES

SERVICE TOOLS

FUEL SYSTEM

SPECIFICATIONS

FUEL RECOMMENDATIONS

FUEL OIL RECOMMENDED PROPERTIES

FUEL SYSTEM

STALL SPEED CHECK LIST

IF THE STALL SPEED IS TOO HIGH, CHECK THE FOLLOWING:

IF THE STALL SPEED IS TOO LOW, CHECK THE FOLLOWING:

STALL SPEED TEST

STALL SPEED CHECK

CONVERTER TRANSMISSIONS STALL SPEED

TIME SPEED CHECK

VS GOVERNER ADJUSTING SCREW SEALING WASHERS

INSTALL

REMOVE

VS GOVERNER IDLE SPRING

INSTALL

REMOVE

INJECTORS AND FUEL LINES - GROUP 06

AFC NO AIR CHECK

MEASURE

AIR IN FUEL

TEST

GEAR PUMP DRAIN METHOD

SIGHTGLASS METHOD

CYLINDER MISFIRES OR SMOKES

AUTOMATED CYLINDER PERFORMANCE TEST

CELECT OR CELECT PLUS

CYLINDER CUTOUT TEST

CELECT OR CELECT PLUS

STC

EXHAUST MANIFOLD TEMPERATURE TEST

EXHAUST MANIFOLD TILT-BACK METHOD

GENERAL INFORMATION

ECM COOLING PLATE

INSTALL

REMOVE

FUEL DRAIN LINE RESTRICTION

MEASURE

FUEL FILTER (SPIN-ON TYPE)

INSTALL

REMOVE

FUEL INLET RESTRICTION

MEASURE

FUEL SUPPLY LINES

INSPECT FOR REUSE

REMOVE

INJECTOR

INSTALL

CELECT OR CELECT PLUS

STC

REMOVE

CELECT OR CELECT PLUS

STC

INJECTORS AND FUEL LINES - GENERAL INFORMATION

THEORY OF OPERATION - CELECT AND CELECT PLUS FUEL SYSTEM

HYDROMECHANICAL SUBSYSTEM

INJECTION CYCLE

THEORY OF OPERATION - PT FUEL SYSTEM

THEORY OF OPERATION - STC FUEL SYSTEM

SERVICE TOOLS

INJECTORS AND FUEL LINES

STATIC INJECTION TIMING

MEASURE

SETUP

STC OIL CONTROL VALVE (MECHANICAL)

INITIAL CHECK

INSTALL

REMOVE

STC OIL DELIVERY SYSTEM BLOCKAGE

INITIAL CHECK

LEAK TEST

STC OIL DELIVERY SYSTEM DIAGNOSTICS

TEST

LUBRICATING OIL SYSTEM - GROUP 07

FLOW DIAGRAM, LUBRICATING OIL SYSTEM

LUBRICATING OIL AND FILTERS

INSPECT

LUBRICATING OIL CONTAMINATION

FLUORESCENT DYE TRACER

FUEL PRESSURE TEST

LUBRICATING OIL COOLER

CLEAN

INSTALL

PRESSURE TEST

REMOVE

LUBRICATING OIL DIPSTICK

CALIBRATE

LUBRICATING OIL DIPSTICK HOUSING

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

LUBRICATING OIL FILTER (CANISTER-TYPE)

LEAK TEST

LUBRICATING OIL FILTER HEAD

ASSEMBLE

CLEAN

DISASSEMBLE

INSPECT FOR REUSE

INSTALL

REMOVE

LUBRICATING OIL FILTER (SPIN ON)

GENERAL INFORMATION

INSTALL

REMOVE

LUBRICATING OIL HIGH PRESSURE RELIEF VALVE

INTIAL CHECK

INSPECT FOR REUSE

INSTALL

REMOVE

LUBRICATING OIL LEAKS

MAINTENANCE CHECK

EXTERNAL

LUBRICATING OIL PAN

CLEAN

DRAIN

FILL

INSPECT FOR REUSE

INSTALL

FRONT SUMP PAN

REAR SUMP PAN

REMOVE

FRONT SUMP PAN

REAR SUMP PAN

LUBRICATING OIL PRESSURE GAUGE

TEST

LUBRICATING OIL PRESSURE REGULATOR (MAIN RIFLE)

INSPECT FOR REUSE

INSTALL

REMOVE

LUBRICATING OIL PUMP

INSPECT FOR REUSE

INSTALL

REMOVE

LUBRICATING OIL SYSTEM

PRIME

LUBRICATING OIL SYSTEM - GENERAL INFORMATION

LUBRICATING OIL TEMPERATURE GAUGE

TEST

LUBRICATING OIL THERMOSTAT

INSPECT FOR REUSE

INSTALL

REMOVE

LUBRICATING OIL TRANSFER TUBE

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

LUBRICATING OIL VISCOSITY SENSOR

INSPECT FOR REUSE

INSTALL

REMOVE

SERVICE TOOLS

LUBRICATING OIL SYSTEM

SPECIFICATIONS

CUMMINS/FLEETGUARD FILTER SPECIFICATIONS

LUBRICATING OIL FILTERS

LUBRICATING OIL SYSTEM

COOLING SYSTEM - GROUP 08

COOLANT FILTER

INSTALL

REMOVE

COOLANT FILTER HEAD

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

COOLANT HEATER HOUSING

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

COOLANT TEMPERATURE GAUGE

INITIAL CHECK

COOLANT THERMOSTAT

INSPECT FOR REUSE

INSTALL

LEAK TEST

REMOVE

COOLANT THERMOSTAT HOUSING SUPPORT

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

COOLANT THERMOSTAT SEAL

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

COOLANT VENT LINES

INITIAL CHECK

COOLING SYSTEM

CLEAN

DRAIN

FILL

PRESSURE TEST

COOLING SYSTEM - AIR OR COMBUSTION GAS TEST

INITIAL TEST

AIR COOLING SYSTEM

LEAK TEST

AIR COMPRESSOR

COMBUSTION GAS LEAK

FAN, SHUTTER, OR HEATER AIR CONTROL VALVE

COOLING SYSTEM - GENERAL INFORMATION

COOLING SYSTEM DIAGNOSTICS

ANALYZING THE DATA

GENERAL INFORMATION

SETUP

TEST

OPERATIONAL WORKSHEET

COOLING SYSTEM PRECHARGE

CUSTOMER PRECHARGE METHOD

FACTORY PRECHARGE METHOD

GENERAL INFORMATION

DRIVE BELT, COOLING FAN

INSPECT FOR REUSE

INSTALL

REMOVE

FAN CLUTCH, AIR-DISENGAGED

GENERAL INFORMATION

MAINTENANCE CHECK

FAN CLUTCH, AIR-ENGAGED

GENERAL INFORMATION

MAINTENANCE CHECK

FAN CLUTCH, ELECTRIC

INSPECT FOR REUSE

INSTALL

REMOVE

FAN CLUTCH, ON-OFF

GENERAL INFORMATION

INITIAL CHECK

FAN CLUTCH, VISCOUS

GENERAL INFORMATION

INITIAL CHECK

INSTALL

REMOVE

FAN, COOLING

INSPECT FOR REUSE

INSTALL

REMOVE

FAN DRIVE IDLER PULLEY ASSEMBLY

INITIAL CHECK

INSTALL

REMOVE

FAN HUB, BELT DRIVEN

INITIAL CHECK

INSTALL

REMOVE

FAN SHROUD ASSEMBLY

INITIAL CHECK

FAN SPACER AND PULLEY

INSPECT FOR REUSE

INSTALL

REMOVE

FLOW DIAGRAM, COOLING SYSTEM

RADIATOR

INITIAL CHECK

RADIATOR HOSES

INSPECT FOR REUSE

RADIATOR PRESSURE CAP

INSPECT FOR REUSE

RADIATOR SHUTTER ASSEMBLY

INITIAL CHECK

SERVICE TOOLS

COOLING SYSTEM

SPECIFICATIONS

COOLANT REPLACEMENT REQUIREMENTS

COOLING SYSTEM

COOLING SYSTEM SEALING ADDITIVES

COOLING SYSTEM SOLUBLE OILS

FLEETGUARD DCA4 SERVICE FILTERS AND LIQUID PRECHARGE

FULLY FORMULATED COOLANT/ANTIFREEZE

GENERAL INFORMATION

SUPPLEMENTAL COOLANT ADDITIVE (SCA)

TEST INTERVALS

TESTING SCA CONCENTRATION LEVEL CC-2602 TEST KIT

PRECAUTIONS AND INSTRUCTIONS FOR PROPER KIT USE

THERMO CONTROL SETTINGS

TORQUE CONVERTER COOLER

GENERAL INFORMATION

WATER PUMP

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

WIRING HARNESS, CUMMINS ELECTRIC FAN CLUTCH

GENERAL INFORMATION

INITIAL CONNECTIONS

INSTALL

REMOVE

DRIVE UNITS - GROUP 09

ACCESSORY DRIVE

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

ACCESSORY DRIVE PULLEY

INSPECT FOR REUSE

INSTALL

REMOVE

ALTERNATOR DRIVE PULLEY

INSPECT FOR REUSE

INSTALL

REMOVE

HYDRAULIC PUMP DRIVE

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

SERVICE TOOLS

DRIVE UNITS

AIR INTAKE SYSTEM - GROUP 10

AFTERCOOLER

CLEAN

INSPECT FOR REUSE

INSTALL

PRESSURE TEST

REMOVE

AIR INTAKE MANIFOLD

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

AIR INTAKE RESTRICTION

MEASURE

AIR INTAKE SYSTEM - GENERAL INFORMATION

GENERAL INFORMATION

AIR LEAKS, AIR INTAKE AND EXHAUST SYSTEMS

MAINTENANCE CHECK

CHARGE AIR COOLER (CAC)

CLEAN

INSPECT FOR REUSE

LEAK TEST

PRESSURE DIFFERENTIAL TEST

TEMPERATURE DIFFERENTIAL TEST

FLOW DIAGRAM, AIR INTAKE SYSTEM

SERVICE TOOLS

AIR INTAKE SYSTEM

SPECIFICATIONS

AIR INTAKE SYSTEM

TURBOCHARGER

CHECK FOR CORRECT COMPONENT

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

TURBOCHARGER AXIAL CLEARANCE

MEASURE

TURBOCHARGER BLADE DAMAGE

INSPECT FOR REUSE

TURBOCHARGER COMPRESSOR SEAL LEAKS

LEAK TEST

TURBOCHARGER RADIAL BEARING CLEARANCE

MEASURE

TURBOCHARGER TURBINE SEAL LEAKS

LEAK TEST

EXHAUST SYSTEM - GROUP 11

EXHAUST MANIFOLD, DRY

ASSEMBLE

CLEAN

DISASSEMBLE

INSPECT FOR REUSE

INSTALL

REMOVE

EXHAUST RESTRICTION

MEASURE

FLOW DIAGRAM, EXHAUST SYSTEM

SPECIFICATIONS

EXHAUST SYSTEM

COMPRESSED AIR SYSTEM - GROUP 12

AIR COMPRESSOR

INSPECT FOR REUSE

INSTALL

REMOVE

AIR COMPRESSOR CARBON BUILDUP

INITIAL CHECK

AIR COMPRESSOR CYLINDER HEAD (HOLSET QE MODELS)

ASSEMBLE

QE, EUROPEAN

QE, NON-EUROPEAN

CLEAN

DISASSEMBLE

INSPECT FOR REUSE

AIR COMPRESSOR CYLINDER HEAD (HOLSET SS AND E-TYPE MODELS)

ASSEMBLE

CLEAN

DISASSEMBLE

INSPECT FOR REUSE

AIR COMPRESSOR CYLINDER HEAD (HOLSET ST MODELS)

ASSEMBLE

CLEAN

DISASSEMBLE

INSPECT FOR REUSE

AIR COMPRESSOR PIN BORE WEAR

INITIAL CHECK

AIR COMPRESSOR UNLOADER AND VALVE ASSEMBLY

CLEAN

INITIAL CHECK

INSPECT FOR REUSE

INSTALL

HOLSET QE MODELS

HOLSET SS, E-TYPE, AND ST MODELS

REMOVE

HOLSET QE MODELS

HOLSET SS, E-TYPE, AND ST MODELS

AIR GOVERNER (AIR COMPRESSOR PUMPS CONTINUOUSLY)

INITIAL CHECK

AIR GOVERNOR (AIR COMPRESSOR WILL NOT PUMP)

INITIAL CHECK

AIR LEAKS, COMPRESSED AIR SYSTEM

INITIAL CHECK

COMPRESSED AIR SYSTEM - GENERAL INFORMATION

SERVICE TOOLS

COMPRESSED AIR SYSTEMS

SPECIFICATIONS

COMPRESSED AIR SYSTEM

HOLSET SS296/SS296E/QE296A/C MODELS

HOLSET SS338/QE338 A/C MODELS

HOLSET ST676 A/C MODEL

ELECTRICAL EQUIPMENT - GROUP 13

ALTERNATOR

INITIAL CHECK

INSTALL

REMOVE

BATTERIES

INITIAL CHECK

BATTERY CABLES AND CONNECTIONS

INITIAL CHECK

DRIVE BELT, ALTERNATOR

ADJUST

ADJUSTMENT LINK TYPE

AUTOMATIC BELT TENSIONER

INSTALL

ADJUSTMENT LINK TYPE

AUTOMATIC BELT TENSIONER

REMOVE

ADJUSTMENT LINK TYPE

AUTOMATIC BELT TENSIONER

ELECTRICAL EQUIPMENT - GENERAL INFORMATION

SERVICE TOOLS

ELECTRICAL EQUIPMENT

SPECIFICATIONS

ELECTRICAL SYSTEM

STARTER MAGNETIC SWITCH

CURRENT CHECK

STARTER SOLENOID

VOLTAGE CHECK

STARTER SWITCH

VOLTAGE

STARTING MOTOR

INSTALL

REMOVE

ENGINE TESTING - GROUP 14

DYNAMOMETER WORKSHEET

ENGINE RUN-IN (CHASSIS DYNAMOMETER)

RUN-IN INSTRUCTIONS

ENGINE RUN-IN (ENGINE DYNAMOMETER)

RUN-IN INSTRUCTIONS

ENGINE RUN-IN (WITHOUT DYNAMOMETER)

RUN-IN INSTRUCTIONS

OFF-HIGHWAY APPLICATIONS

ON-HIGHWAY APPLICATIONS

ENGINE TESTING - GENERAL INFORMATION

FUEL FLOW MEASUREMENT ON ENGINE OR CHASSIS DYNAMOMETER

ENGINE TESTING (CHASSIS DYNAMOMETER)

SETUP

TEST

ENGINE TESTING (ENGINE DYNAMOMETER)

SETUP

ENGINE TESTING (PORTABLE DYNAMOMETER OR LOAD BANK)

GENERAL INFORMATION

SERVICE TOOLS

ENGINE TESTING

SPECIFICATIONS

ENGINE TESTING

MOUNTING ADAPTATIONS - GROUP 16

ENGINE LIFTING BRACKETS

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

ENGINE SUPPORT BRACKET, FRONT

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

FLYWHEEL

CLEAN

INSPECT FOR REUSE

INSTALL

MEASURE

BORE RUN OUT

FACE RUN OUT

REMOVE

FLYWHEEL HOUSING

CLEAN

INSPECT FOR REUSE

INSTALL

MEASURE

FACE ALIGNMENT

BORE ALIGNMENT

REMOVE

FLYWHEEL HOUSING, REPTO

CLEAN

INSPECT FOR REUSE

INSTALL

MEASURE

BORE ALIGNMENT

FACE ALIGNMENT

REMOVE

FLYWHEEL RING GEAR

INSTALL

REMOVE

SERVICE TOOLS

MOUNTING ADAPTATIONS

MISCELLANEOUS HARDWARE - GROUP 17

CUP PLUG

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

PIPE PLUG

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

STRAIGHT THREAD PLUG

CLEAN

INSPECT FOR REUSE

INSTALL

REMOVE

VEHICLE BRAKING - GROUP 209

ENGINE BRAKE

ADJUST

CLEAN

INITIAL CHECK

INSPECT FOR REUSE

INSTALL

REMOVE

SERVICE LITERATURE

ADDITIONAL SERVICE LITERATURE

LITERATURE ORDER FORM

SERVICE LITERATURE ORDERING LOCATION

COMPONENT MANUFACTURERS

COMPONENT MANUFACTURERS' ADDRESSES

AIR COMPRESSORS

AIR CYLINDERS

AIR HEATERS

AIR STARTING MOTORS

ALTERNATORS

AUXILIARY BRAKES

BELTS

CATALYTIC CONVERTORS

CLUTCHES

COOLANT HEATERS

COOLANT LEVEL SWITCHES

DRIVE PLATES

ELECTRIC STARTING MOTORS

ELECTRONIC SWITCHES

ENGINE PROTECTION SWITCHES

FAN CLUTCHES

FANS

FAULT LAMPS

FILTERS

FLEXPLATES

FUEL COOLERS

FUEL WARMERS

GAUGES

GOVERNORS

HEAT SLEEVES

HYDRAULIC AND POWER STEERING PUMPS

IN-LINE CONNECTORS

OIL HEATERS

PRELUBRICATION SYSTEMS

READIATORS

THROTTLE ASSEMBLIES

TORQUE CONVERTERS

SPECIFICATIONS

AIR INTAKE SYSTEM - SPECIFICATIONS

AIR INTAKE RESTRICTION

TURBOCHARGER AXIAL CLEARANCE

TURBOCHARGER RADIAL BEARING CLEARANCE

AIR INTAKE SYSTEM - TORQUE VALUES

AFTERCOOLER

AIR INTAKE MANIFOLD

AIR LEAKS, AIR INTAKE AND EXHAUST SYSTEMS

TURBOCHARGER

CAM FOLLOWERS/TAPPETS - SPECIFICATIONS

CAM FOLLOWER ASSEMBLY

CAM FOLLOWERS/TAPPETS - TORQUE VALUES

CAM FOLLOWER ASSEMBLY

CAPSCREW MARKINGS AND TORQUE VALUES

CAPSCREW MARKINGS AND TORQUE VALUES - METRIC

CAPSCREW MARKINGS AND TORQUE VALUES - U.S. CUSTOMARY

COMPRESSED AIR SYSTEM - TORQUE VALUES

AIR COMPRESSOR

AIR COMPRESSOR CYLINDER HEAD (HOLSET QE MODELS)

AIR COMPRESSOR CYLINDER HEAD (HOLSET SS AND E-TYPE MODELS)

AIR COMPRESSOR CYLINDER HEAD (HOLSET ST MODELS)

AIR COMPRESSOR UNLOADER AND VALVE ASSEMBLY

COOLING SYSTEM - SPECIFICATIONS

COOLANT THERMOSTAT

FAN DRIVE IDLER PULLEY ASSEMBLY

FAN HUB, BELT DRIVEN

WATER PUMP

COOLING SYSTEM - TORQUE VALUES

COOLANT FILTER HEAD

COOLANT HEATER HOUSING

COOLANT THERMOSTAT

COOLANT THERMOSTAT HOUSING SUPPORT

DRIVE BELT, COOLING FAN

FAN CLUTCH, ELECTRIC

FAN CLUTCH, VISCOUS

FAN, COOLING

FAN HUB, BELT DRIVEN

FAN SPACER AND PULLEY

WATER PUMP

CYLINDER BLOCK - SPECIFICATIONS

BEARINGS, CONNECTING ROD

BEARINGS, MAIN

BEARINGS, THRUST

CAMSHAFT

CAMSHAFT BUSHINGS

CAMSHAFT GEAR (CAMSHAFT INSTALLED)

CONNECTING ROD

CRANKSHAFT GEAR, FRONT (CRANKSHAFT INSTALLED)

CYLINDER LINER PROTRUSTION

GEAR HOUSING, FRONT

IDLER GEAR, CAMSHAFT

IDLER GEAR, HYDRAULIC PUMP

IDLER GEAR, WATER PUMP

PISTON COOLING NOZZLE

PISTON RINGS

CYLINDER BLOCK - TORQUE VALUES

ACCESSORY DRIVE SEAL

ALTERNATOR DRIVE SEAL

BEARINGS, MAIN

CAMSHAFT

CRANKSHAFT PULLEY

CRANKSHAFT SEAL, FRONT

CRANKSHAFT SEAL, REAR

CYLINDER LINER PROTRUSION

GEAR COVER, FRONT

GEAR HOUSING, FRONT

IDLER GEAR, CAMSHAFT

IDLER GEAR, HYDRAULIC PUMP

IDLER GEAR, WATER PUMP

PISTON AND CONNECTING ROD ASSEMBLY

PISTON COOLING NOZZLE

WATER HEADER PLATE, CYLINDER BLOCK

CLYINDER HEAD - SPECIFICATIONS

CYLINDER HEAD

CYLINDER HEAD - TORQUE VALUES

CYLINDER HEAD

DRIVE BELT TENSION

DRIVE UNITS - SPECIFICATIONS

ACCESSORY DRIVE

HYDRAULIC PUMP DRIVE

DRIVE UNITS - TORQUE VALUES

ACCESSORY DRIVE

ACCESSORY DRIVE PULLEY

ALTERNATOR DRIVE PULLEY

HYDRUALIC PUMP DRIVE

ELECTRICAL EQUIPMENT - TORQUE VALUES

ALTERNATOR

DRIVE BELT, ALTERNATOR

STARTING MOTOR

EXHAUST SYSTEM - SPECIFICATIONS

EXHAUST RESTRICTION

EXHAUST SYSTEM - TORQUE VALUES

EXHAUST MANIFOLD, DRY

FRACTION, DECIMAL, MILLIMETER CONVERSIONS

FUEL SYSTEM - SPECIFICATIONS

FUEL FLOW

FUEL SYSTEM - TORQUE VALUES

FUEL PUMP

FUEL PUMP GEAR PUMP CHECK VALVE

FUEL PUMP PULSATION DAMPER

FUEL PUMP VS THROTTLE SHAFT HOUSING

FUEL SHUTOFF VALVE

INJECTION TIMING CODES

INJECTORS AND FUEL LINES - SPECIFICATIONS

FUEL DRAIN LINE RESTRICTION

FUEL INLET RESTRICTION

INJECTORS AND FUEL LINES - TORQUE VALUES

ECM COOLING PLATES

INJECTOR

STC OIL CONTROL VALVE (MECHANICAL)

LUBRICATING OIL SYSTEM - SPECIFICATION

LUBRICATING OIL HIGH PRESSURE RELIEF VALVE

LUBRICATING OIL PRESSURE REGULATOR (MAIN RIFLE)

LUBRICATING OIL PUMP

LUBRICATING OIL SYSTEM - TORQUE VALUES

LUBRICATING OIL COOLER

LUBRICATING OIL DIPSTICK HOUSING

LUBRICATING OIL FILTER HEAD

LUBRICATING OIL PAN

LUBRICATING OIL PRESSURE REGULATOR (MAIN RIFLE)

LUBRICATING OIL PUMP

LUBRICATING TRANSFER TUBE

LUBRICATING OIL VISCOSITY SENSOR

MISCELLANEOUS - SPECIFICATIONS

MOUNTING ADAPTATIONS - SPECIFICATIONS

FLYWHEEL HOUSING

MOUNTING ADAPTATIONS - TORQUE VALUES

ENGINE LIFTING BRACKETS

ENGINE SUPPORT BRACKET, FRONT

FLYWHEEL

FLYWHEEL HOUSING

FLYWHEEL HOUSING, REPTO

NEWTON-METER TO FOOT-POUND CONVERSION CHART

PIPE PLUG TORQUE VALUES

ROCKER LEVERS - SPECIFICATIONS

OVERHEAD SET

ROCKER LEVER ASSEMBLY

ROCKER LEVERS - TORQUE VALUES

CRANKCASE BREATHER (INTERNAL

ROCKER LEVER ASSEMBLY

ROCKER LEVER COVER

ROCKER LEVER HOUSING

TAP-DRILL CHART - U.S. CUSTOMARY AND METRIC

VEHICLE BRAKING - TORQUE VALUES

ENGINE BRAKE

WEIGHT AND MEASURES - CONVERSION FACTORE

INDEX

-