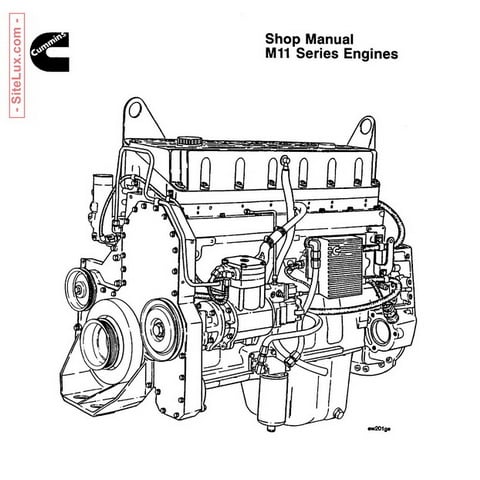

Cummins M11 Series Engines Service Repair Shop Manual

-

This complete service repair workshop manual PDF download for the Cummins M11 Series Engines has easy-to-read text sections with top quality diagrams, pictures and illustrations. The step by step instructions show you how to fault find or complete any repair or overhaul, correctly and efficiently, saving time and avoiding costly mistakes.

This manual contains complete rebuild specifications and information for the M11 model engines, and all associated components manufactured by Cummins Engine Company, Inc.

TABLE OF CONTENTS :

Introduction

Engine Identification

Engine Disassembly and Assembly – Group 00

Cylinder Block – Group 01

Cylinder Head – Group 02

Rocker Levers – Group 03

Cam Followers – Group 04

Fuel System – Group 05

Injectors and Fuel Lines – Group 06

Lubricating Oil System – Group 07

Cooling System – Group 08

Drive Units – Group 09

Air Intake System – Group 10

Exhaust System – Group 11

Air Equipment – Group 12

Electrical Equipment – Group 13

Engine Testing – Group 14

Instruments and Controls – Group 15

Mounting Adaptations – Group 16

Specifications – Group 18

Vehicle Braking – Group 20

Service Literature

Component Manufacturers: Names and Addresses

Index

MANUAL SPECIFICATION :

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bulletin No. : 3666075-00

Total Pages : 585

This (OEM) manual pdf download has detailed illustrations as well as step by step instructions, It is 100 percents complete and intact. they are specifically written for the do-it-yourself-er as well as the experienced mechanic. With step by step instruction & highly detailed exploded pictures & diagrams to show you how to complete the required job correctly & efficiently Using. Provides step-by-step instructions based on the complete dis-assembly of the machine. It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. Complete download comes in pdf format which can work under all PC based windows operating system and Mac also, All pages are printable. Using this repair manual is an inexpensive way to keep your vehicle working properly.

This service repair workshop manual PDF download has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This is a must for the Do-It-Yourselfer! Saving Yourself $$$$$$ In Service Repair And Maintenance Costs !!!!

This service repair workshop manual PDF download contains specs, diagrams, actual real photo illustrations, and schemes. In addition to space savings, nice thing about having completly searcheble PDF files instead of a hard-printed manual is that you can use the Search feature in your PDF reader software (Adobe Acrobat) to find just what your looking for and just print out the exact pages you need or all manual easily. This is the same Repair Service manual your local dealer will use when doing a repair.

Instant Download means there is NO shipping costs or waiting for a CD or paper manual to arrive in the mail!, You will receive this manual TODAY via Instant Download on completion of payment via our secure payment processor. We accept ALL major credit/debit cards/paypal.

More Info : https://www.sitelux.com

-

MAIN MENU

COVER PAGE

TABLE OF CONTENTS

INTRODUCTION

ABOUT THE MANUAL

DEFINITION OF TERMS

GENERAL CLEANING INSTRUCTIONS

GLASS OR PLASTIC BEAD CLEANING

SOLVENT OR ACID CLEANING

STEAM CLEANING

GENERAL REPAIR INSTRUCTIONS

WELDING ON A CELECT CONTROLLED VEHICLE

GENERAL SAFETY INSTRUCTIONS

IMPORTANT SAFETY NOTICE

HOW TO USE THE MANUAL

ILLUSTRATIONS

SIMBOLOS

SYMBOLE

SYMBOLES

SYMBOLS

ENGINE IDENTIFICATION

ENGINE DIAGRAMS

ENGINE INDENTIFICATION

ELECTRONIC CONTROL MODULE (ECM) DATAPLATE

ENGINE DATAPLATE

ENGINE SPECIFICATIONS

AIR INTAKE SYSTEM

BATTERIES (SPECIFIC GRAVITY)

COOLING SYSTEM

ELECTRICAL SYSTEM

EXHAUST SYSTEM

FUEL SYSTEM

GENERAL ENGINE DATA

LUBRICATING OIL SYSTEM

ENGINE DISASSEMBLY AND ASSEMBLY - GROUP 00

ENGINE ASSEMBLY

ACCESSORY DRIVE ASSEMBLY - INSTALLATION

ACCESSORY DRIVE OIL SEAL - INSTALLATION

ACCESSORY DRIVE PULLEY - INSTALLATION

ACTUATOR HARNESS - INSTALLATION

AIR COMPRESSOR - INSTALLATION

AIR COMPRESSOR AIR SUPPLY TUBE - INSTALLATION

AIR COMPRESSOR COOLANT INLET TUBE FITTING - INSTALLATION

AIR COMPRESSOR COOLANT OUTLET TUBE - INSTALLATION

AIR INTAKE MANIFOLD - INSTALLATION

ALTERNATOR - INSTALLATION

ALTERNATOR AND BRACKET (BUS APPLICATIONS) - INSTALLATION

ALTERNATOR BELT (NON BUS APPLICATIONS) - INSTALLATION

ALTERNATOR DRIVE BELT (BUS APPLICATIONS) - INSTALLATION

ALTERNATOR DRIVE PULLEY - INSTALLATION

ALTERNATOR DRIVE SEAL - INSTALLATION

AUTOMATIC BELT TENSIONER - INSTALLATION

CAM FOLLOWER ASSEMBLIES - INSTALLATION

CAMSHAFT AND GEAR ASSEMBLY - INSTALLATION

CONNECTING ROD SIDE CLEARANCE MEASUREMENT

COOLANT FILTER - INTSTALLATION

CRANKSHAFT - INSTALLATION

CROSSHEADS - INSTALLATION

CYLINDER BLOCK - INSTALLATION ON REBUILD STAND

CYLINDER HEAD - INSTALLATION

CYLINDER LINERS - INSTALLATION

DIPSTICK TUBE BRACKET - INSTALLATION

DRAIN PLUGS - INSPECTION

ELECTRIC FAN CLUTCH (CUMMINS) - INSTALLATION

ELECTRONIC CONTROL COOLING PLATE - INSTALLATION

ELECTRONIC CONTROL MODULE - INSTALLATION

ENGINE - REMOVAL FROM THE REBUILD STAND

EXHAUST MANIFOLD - INSTALLATION

FAN BELT - INSTALLATION

FAN HUB (BELT DRIVEN) - INSTALLATION

FAN HUB SUPPORT - INSTALLATION

FAN IDLER PULLEY - INSTALLATION

FAN PULLEY AND FAN - INSTALLATION

FLYWHEEL - INSTALLATION

FLYWHEEL BORE RUNOUT - MEASUREMENT

FLYWHEEL FACE RUNOUT - MEASUREMENT

FLYWHEEL HOUSING - INSTALLATION

FLYWHEEL HOUSING BORE ALIGNMENT - MEASUREMENT

FLYWHEEL HOUSING FACE ALIGNMENT - MEASUREMENT

FLYWHEEL HOUSING, REPTO - INSTALLATION

FRONT CRANKSHAFT OIL SEAL - INSTALLATION

FUEL FILTER - INSTALLATION

FUEL FILTER HEAD AND BRACKET - INSTALLATION

FUEL PUMP PLUMBING - INSTALLATION

FUEL PUMP SUPPORT BRACKET - INSTALLATION

FUEL PUMP (WITH AIR COMPRESSOR) - INSTALLATION

FUEL PUMP (WITHOUT AIR COMPRESSOR) - INSTALLATION

GEAR COVER - INSTALLATION

GEAR HOUSING - INSTALLATION

HAND HOLE COVER (EXHAUST SIDE OF ENGINE ) - INSTALLATION

HAND HOLE COVER (FUEL PUMP SIDE OF ENGINE ) - INSTALLATION

HIGH OIL PRESSURE REGULATOR - INSTALLATION

HYDRAULIC PUMP DRIVE - INSTALLATION

IDLER GEAR ASSEMBLIES - INSTALLATION

IDLER GEAR (REPTO) - INSTALLATION

INJECTORS - INSTALLATION

JACOBS BRAKE HOUSING SPACER - INSTALLATION

JACOBS BRAKE OIL SUPPLY HOSE - INSTALLATION

JACOBS ENGINE BRAKE - INSTALLATION

LUBRICATING OIL COOLER - INSTALLATION

LUBRICATING OIL FILTER - INSTALLATION

LUBRICATING OIL FILTER HEAD - INSTALLATION

LUBRICATING OIL PAN - INSTALLATION

LUBRICATING OIL PUMP - INSTALLATION

MAIN OIL PRESSURE REGULATOR - INSTALLATION

OVERHEAD - ADJUSTMENT

PISTON AND CONNECTING ROD - ASSEMBLY

PISTON AND CONNECTING ROD - INSTALLATION

PISTON COOLING NOOZLE - INSTALLATION

PUSH RODS AND TUBES - INSTALLATION

REAR CRANKSHAFT OIL SEAL - INSTALLATION

ROCKER LEVER ASSEMBLIES - INSTALLATION

ROCKER LEVER COVER - INSTALLATION

ROCKER LEVER HOUSING - INSTALLATION

ROCKER LEVER SIDE CLEARANCE - ADJUSTMENT

SENSOR HARNESS - INSTALLATION

STARTING MOTOR - INSTALLATION

STATIC INJECTION TIMING - CHECKING

STATIC INJECTION TIMING - GENERAL INFORMATION

THERMOSTAT HOUSING - INSTALLATION

THERMOSTAT HOUSING SUPPORT - INSTALLATION

THRUST BEARING, LOWER BEARING SHELLS AND MAIN BEARING CAPS - INSTALLATION

TORQUE CONVERTER COOLER DISC - INSTALLATION

TURBOCHARGER - INSTALLATION

TURBOCHARGER DRAIN FITTING - INSTALLATION

UPPER MAIN BEARING SHELLS - INFORMATION

VIBRATION DAMPER AND CRANKSHAFT PULLEY - INSTALLATION

VIBRATION DAMPER ECCENTRICITY - MEASUREMENT

VIBRATION DAMPER FACE - RUNOUT MEASUREMENT

VISCOSITY SENSOR - INSTALLATION

WATER FILTER HEAD - INSTALLATION

WATER HEADER PLATE - INSTALLATION

WATER HEATER HOUSING - INSTALLATION

WATER PUMP - INSTALLATION

ENGINE DISASSEMBLY

ACCESSORY DRIVE ASSEMBLY - REMOVAL

ACCESSORY DRIVE OIL SEAL - REMOVAL

ACCESSORY DRIVE PULLEY - REMOVAL

AIR COMPRESSOR - REMOVAL

AIR COMPRESSOR AIR SUPPLY TUBE - REMOVAL

AIR COMPRESSOR COOLANT TUBES - REMOVAL

AIR INTAKE MANIFOLD - REMOVAL

ALTERNATOR ADJUSTING LINK (NON BUS APPLICATIONS) - REMOVAL

ALTERNATOR AND BRACKET (NON BUS APPLICATIONS) - REMOVAL

ALTERNATOR AND BRACKETS (BUS APPLICATIONS)

ALTERNATOR BELT (BUS APPLICATIONS) - REMOVAL

ALTERNATOR BELT (NON BUS APPLICATIONS) - REMOVAL

ALTERNATOR DRIVE OIL SEAL - REMOVAL

ALTERNATOR DRIVE PULLEY - REMOVAL

BLOCK MOUNTED FRONT SUMP SUCTION TUBE - REMOVAL

CAM FOLLOWER ASSEMBLIES - REMOVAL

CAMSHAFT - REMOVAL

COOLANT - DRAINING

COOLANT FILTER - REMOVAL

CRANKSHAFT AND UPPER MAIN BEARING SHELLS - REMOVAL

CRANKSHAFT FRONT OIL SEAL - REMOVAL

CRANKSHAFT PULLEY AND VIBRATION DAMPER - REMOVAL

CRANKSHAFT REAR OIL SEAL - REMOVAL

CROSSHEADS - REMOVAL

CYLINDER HEAD - REMOVAL

CYLINDER LINERS - REMOVAL

ELECTRONIC CONTROL COOLING PLATE - REMOVAL

ELECTRONIC CONTROL MODULE - REMOVAL

ENGINE - CLEANING

ENGINE - INSTALLATION ON REBUILD STAND

ENGINE - PREPARATION FOR CLEANING

ENGINE BARRING TOOL - INSTALLATION

EXHAUST MANIFOLD - REMOVAL

FAN AND FAN HUB - REMOVAL

FAN DRIVE BELT - REMOVAL

FAN HUB SUPPORT - REMOVAL

FLYWHEEL - REMOVAL

FLYWHEEL HOUSING - REMOVAL

FLYWHEEL HOUSING, REPTO - REMOVAL

FRONT ENGINE SUPPORT BRACKET - REMOVAL

FUEL FILTER - REMOVAL

FUEL LINES - REMOVAL

FUEL PUMP - REMOVAL

FUEL SUPPLY HOSE AND FILTER HEAD - REMOVAL

GEAR COVER - REMOVAL

GEAR HOUSING - REMOVAL

HAND HOLE COVER AND DIPSTICK TUBE BRACKET - REMOVAL

HAND HOLE COVER (FUEL PUMP SIDE) - REMOVAL

HIGH OIL PRESSURE REGULATOR - REMOVAL

HYDRAULIC PUMP DRIVE - REMOVAL

HYDRAULIC PUMP OR COVER - REMOVAL

IDLER GEAR ASSEMBLIES - REMOVAL

INJECTORS - REMOVAL

INTERNAL ACTUATOR HARNESS - REMOVAL

JACOBS ENGINE BRAKE - REMOVAL

LIFTING BRACKETS - REMOVAL

LUBRICATING OIL - DRAINING

LUBRICATING OIL COOLER - REMOVAL

LUBRICATING OIL FILTER HEAD - REMOVAL

LUBRICATING OIL FILTERS - REMOVAL

LUBRICATING OIL PAN - REMOVAL

LUBRICATING OIL PUMP - REMOVAL

LUBRICATING OIL TRANSFER TUBE - REMOVAL

MAIN BEARING CAPS, LOWER BEARING SHELLS AND THRUST BEARINGS - REMOVAL

MAIN OIL PRESSURE REGULATOR - REMOVAL

PISTON COOLING NOZZLES - REMOVAL

PISTONS AND CONNECTING ROD - DISASSEMBLY

PISTONS AND CONNECTING RODS - REMOVAL

PUSH RODS - REMOVAL

ROCKER LEVER ASSEMBLIES - REMOVAL

ROCKER LEVER COVER - REMOVAL

ROCKER LEVER HOUSING - REMOVAL

ROCKER LEVER HOUSING SPACER - REMOVAL

SENSOR HARNESS AND SENSORS REMOVAL

STARTING MOTOR - REMOVAL

THERMOSTAT HOUSING - REMOVAL

THERMOSTAT HOUSING SUPPORT - REMOVAL

TORQUE CONVERTER COOLER DISC - REMOVAL

TURBOCHARGER - REMOVAL

TURBOCHARGER OIL DRAIN CONNECTION - REMOVAL

VISCOSITY SENSOR - REMOVAL

WATER FILTER HEAD - REMOVAL

WATER HEADER PLATE - REMOVAL

WATER HEATER HOUSING - REMOVAL

WATER PUMP - REMOVAL

ENGINE DISASSEMBLY AND ASSEMBLY - GENERAL INFORMATION

ASSEMBLY

DISASSEMBLY

ENGINE LIFTING BRACKETS

SERVICE TOOLS - DISASSEMBLY AND ASSEMBLY

CYLINDER BLOCK - GROUP 01

CAMSHAFT - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

CAMSHAFT - MAGNETIC CRACK INSPECTION

BEARING JOURNAL - LIMITS OF ACCEPTANCE

DEFINITIONS OF INDICATIONS

VALVE AND INJECTOR LOBE - LIMITS OF ACCEPTANCE

CAMSHAFT BUSHING - REPLACEMENT

CLEANING

INSPECTION

INSTALLATION

REMOVAL

CAMSHAFT GEAR - REPLACEMENT

CLEANING

INSPECTION

INSTALLATION

REMOVAL

CAMSHAFT OR IDLER GEAR - MAGNETIC CRACK INSPECTION

CAMSHAFT OR IDLER GEAR - LIMITS OF ACCEPTANCE

DEFINITIONS OF INDICATION

CONNECTING ROD - BEND AND TWIST INSPECTION

ALIGNMENT INSPECTION

FIXTURE CALIBRATION

TWIST INSPECTION

CONNECTING ROD - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

CONNECTING ROD - MAGNETIC CRACK INSPECTION

CONNECTING ROD - LIMITS OF ACCEPTANCE

CONNECTING ROD BEARINGS - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

CRANKSHAFT - CLEANING AND INSPECTIONS FOR REUSE

CLEANING

INSPECTION

CRANKSHAFT GEAR - REPLACEMENT

INSPECTION

INSTALLATION

REMOVAL

CRANKSHAFT MAGNETIC CRACK INSPECTION

COIL SHOT (CIRCUMFERENTAL MAGNETIZATION)

HEAD SHOT (LONGITUDINAL MAGNETIZATION)

MAGNETIC INSPECTION - LIMITS OF ACCEPTANCE

CRANKSHAFT PULLEY - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

CYLINDER BLOCK - EXPLODED VIEW

CYLINDER BLOCK - GENERAL INFORMATION

CYLINDER BLOCK - INSPECTION FOR REUSE

CAMSHAFT BUSHING INSIDE DIAMETER

CYLINDER LINER BORES - INSPECTION

HIGH OIL PRESSURE REGULATOR SEAT DEPTH - MEASUREMENT

IDLER GEAR RING DOWEL BORE - MEASUREMENT

MAIN BEARING BORE ALIGNMENT - INSPECTION

MAIN BEARING BORE INSIDE DIAMETER - MEASUREMENT

MAIN OIL PRESSURE REGULATOR VALVE BORE - MEASUREMENT

THRUST BEARING SURFACE WIDTH - MEASUREMENT

CYLINDER BLOCK

ASSEMBLY

CAM FOLLOWER STUDS - INSTALLATION

DOWEL PINS - INSTALLATION

PIPE PLUGS - INSTALLATION

CLEANING

DISASSEMBLY

CAM FOLLOWER STUDS - REMOVAL

DOWEL PINS - REMOVAL

IDLER SHAFT RING DOWELS - REMOVAL

PIPE PLUGS - REMOVAL

CYLINDER LINER - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

DIPSTICK TUBE BRACKET - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

GEAR COVER - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

GEAR HOUSING - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

NEEDLE BEARING INSTALLATION

HAND HOLE COVER - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

IDLER GEAR ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

MAIN BEARINGS - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

PISTON - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

PISTION RINGS - REMOVAL

SERVICE TOOLS - CYLINDER BLOCK

VIBRATION DAMPER (VISCOUS) - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

CYLINDER HEAD - GROUP 02

CYLINDER HEAD - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

CYLINDER HEAD - EXPLODED VIEW

CYLINDER HEAD - GENERAL INFORMATION

CYLINDER HEAD - PRESSURE TEST FOR REUSE

CYLINDER HEAD - REBUILD

ASSEMBLY

DISASSEMBLY

INSPECTION

VALVE SEATS - GRINDING

CYLINDER HEAD - VACUUM TEST VALVE SEATING

CYLINDER HEAD - VALVE GRINDING

INSPECTION

CYLINDER HEAD INJECTOR SLEEVE - REPLACEMENT

ASSEMBLY

DISASSEMBLY

INSPECTION

CYLINDER HEAD OVERSIZE VALVE SEAT INSERT - INSTALLATION

CYLINDER HEAD VALVE GUIDE - REPLACEMENT

ASSEMBLY

DISASSEMBLY

ASSEMBLY

CYLINDER HEAD VALVE SEAT INSERT - REPLACEMENT

ASSEMBLY

DISASSEMBLY

INSPECTION

CYLINDER HEAD VALVES - MAGNETIC CRACK INSPECTION

SERVICE TOOLS - CYLINDER HEAD

VALVE CROSSHEAD - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

VALVE CROSSHEAD - MAGNETIC CRACK INSPECTION

ROCKER LEVERS - GROUP 03

CRANKCASE BREATHER (INTERNAL) - CLEANING AND INSPECTION

ROCKER HOUSING AND COVER (AUTOMOTIVE) - EXPLODED VIEW

ROCKER LEVER - MAGNETIC CRACK INSPECTION

ROCKER LEVER ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

ASSEMBLY

DISASSEMBLY

INSPECTION

ROCKER LEVER ASSEMBLY - REBUILD

ASSEMBLY

DISASSEMBLY

INSPECTION

ROCKER LEVER BUSHING - REPLACEMENT

ASSEMBLY

DISASSEMBLY

INSPECTION

ROCKER LEVER COVER - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

ROCKER LEVER HOUSING - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

ROCKER LEVERS - EXPLODED VIEW

ROCKER LEVERS - GENERAL INFORMATION

SERVICE TOOLS - ROCKER LEVERS

CAM FOLLOWERS - GROUP 04

CAM FOLLOWER ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

ASSEMBLY

DISASSEMBLY

INSPECTION

CAM FOLLOWER ASSEMBLY - EXPLODED VIEW

CAM FOLLOWER ASSEMBLY - GENERAL INFORMATION

CAM FOLLOWER ASSEMBLY - REBUILD

ASSEMBLY

DISASSEMBLY

INSPECTION

CAM FOLLOWER LEVER - MAGNETIC CRACK INSPECTION (ROLLER REMOVED)

CAM FOLLOWER LEVER - ROLLER REPLACEMENT

ASSEMBLY

DISASSEMBLY

INSPECTION

CAM FOLLOWER LEVER SOCKET - REPLACEMENT (ROLLER REMOVED)

ASSEMBLY

DISASSEMBLY

INSPECTION

PUSH RODS AND TUBES - CLEANING AND INSPECTION FOR REUSE

INSPECTION

SERVICE TOOLS - CAM FOLLOWER ASSEMBLY

FUEL SYSTEM - GROUP 05

FUEL PUMP - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

FUEL PUMP - GENERAL INFORMATION

FUEL PUMP - REBUILD

ASSEMBLY

DISASSEMBLY

FUEL DAMPER - ASSEMBLY

FUEL DAMPER - DISASSEMBLY AND INSPECTION

FUEL SHUTOFF VALVE - ASSEMBLY

FUEL SHUTOFF VALVE - CLEANING AND INSPECTION

FUEL SHUTOFF VALVE - DISASSEMBLY

FUEL SUPPLY PUMP - TEST

INSPECTION

INJECTORS AND FUEL LINES - GROUP 06

FUEL TUBES, FITTINGS AND MOUNTING PARTS - CLEANING AND INSPECTION FOR REUSE

INSPECTION

INJECTOR - CELECT - EXPLODED VIEW

INJECTORS - CALIBRATION

INJECTORS - CLEANING AND INSPECTION FOR REUSE

INSPECTION

INJECTORS - GENERAL INFORMATION

INJECTORS - REBUILD

LUBRICATING OIL SYSTEM - GROUP 07

LUBRICATING OIL COOLER - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

PRESSURE TEST THE OIL COOLER ELEMENT

LUBRICATING OIL DIPSTICK - CALIBRATION

LUBRICATING OIL DIPSTICK AND DIPSTICK TUBE - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

LUBRICATING OIL FILTER HEAD - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

LUBRICATING OIL FILTER HEAD - REBUILD

ASSEMBLY

DISASSEMBLY

LUBRICATING OIL PAN - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

LUBRICATING OIL PAN TRANSFER TUBE - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

LUBRICATING OIL PUMP - CLEANING AND INSPECTION FOR REUSE

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

LUBRICATING OIL PUMP - REBUILD

LUBRICATING OIL SYSTEM - EXPLODED VIEW

LUBRICATING OIL SYSTEM - GENERAL INFORMATION

SERVICE TOOLS - LUBRICATING OIL SYSTEM

COOLING SYSTEM - GROUP 08

FAN HUB - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

FAN HUB - EXPLODED VIEW

FAN HUB AND FAN IDLER PULLEY - GENERAL INFORMATION

FAN HUB (BELT DRIVEN) - REBUILD

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

FAN IDLER PULLEY - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

FAN IDLER PULLEY - REBUILD

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

FAN IDLER PULLEY AND BRACKET - EXPLODED VIEW

HEATER HOUSING, THERMOSTAT SUPPORT AND WATER HEADER COVER - CLEANING AND INSPECTION

CLEANING

INSPECTION

SERVICE TOOLS - COOLING SYSTEM

THERMOSTAT - OPERATING TEMPERATURE INSPECTION

TEST

THERMOSTAT HOUSING ASSEMBLY - REBUILD

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

WATER FILTER HEAD ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

WATER FILTER HEAD ASSEMBLY - REBUILD

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

WATER PUMP - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

WATER PUMP - REBUILD

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

WATER PUMP ASSEMBLY - EXPLODED VIEW

WATER PUMP ASSEMBLY - GENERAL INFORMATION

DRIVE UNITS - GROUP 09

ACCESSORY DRIVE PULLEY - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

DRIVE UNITS - GENERAL INFORMATION

FUEL PUMP AND COMPRESSOR DRIVE

HYDRAULIC PUMP DRIVE

FUEL PUMP AND COMPRESSOR DRIVE - CLEANING INSPECTION FOR REUSE

CLEANING

INSPECTION

FUEL PUMP AND COMPRESSOR DRIVE - EXPLODED VIEW

FUEL PUMP AND COMPRESSOR DRIVE - REBUILD

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

HYDRAULIC PUMP DRIVE - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

HYDRAULIC PUMP DRIVE - EXPLODED VIEW

HYDRAULIC PUMP DRIVE - REBUILD

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

SERVICE TOOLS - DRIVE UNITS

AIR INTAKE SYSTEM - GROUP 10

AIR INTAKE SYSTEM - GENERAL INFORMATION

CAC AIR INTAKE SYSTEM EXPODED VIEW

INTAKE MANIFOLD - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

SERVICE TOOLS - AIR INTAKE SYSTEM

TURBOCHARGER - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

EXHAUST SYSTEM - GROUP 11

EXHAUST MANIFOLD - CLEANING INSPECTION FOR REUSE

CLEANING

DISASSEMBLY

INSPECTION

EXHAUST SYSTEM - EXPLODED VIEW

EXHAUST SYSTEM - GENERAL INFORMATION

AIR EQUIPMENT - GROUP 12

AIR COMPRESSOR - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

AIR EQUIPMENT - GENERAL INFORMATION

COMPRESSED AIR SYSTEMS FLOW DIAGRAMS

ELECTRICAL EQUIPMENT - GROUP 13

ALTERNATOR ADJUSTING LINK - CLEANING AND INSPECTION FOR REUSE

INSPECTION

ALTERNATOR BRACKET - CLEANING AND INSPECTION FOR REUSE

INSPECTION

ALTERNATOR BRACKET (BUS APPLICATIONS) - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

AUTOMATIC BELT TENSIONER BRACKET (BUS APPLICATIONS) - CLEANING AND INSPECTION FOR REUSE

CLEANING

AUTOMATIC BELT TENSIONER (BUS APPLICATIONS) - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

ELECTRICAL EQUIPMENT - GENERAL INFORMATION

STARTING MOTOR - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

WIRING DIAGRAMS

ENGINE TESTING - GROUP 14

CHASSIS DYNAMOMETER

GENERAL TEST PROCEDURE

CHARGE AIR COOLER RESTRICTION

COOLANT PRESSURE

ENGINE BLOWBY

ENGINE SPEED (RPM) WITH A VERIFIED TACHOMETER

EXHAUST AIR RESTRICTION

FUEL DRAIN LINE RESTRICTION

FUEL INLET RESTRICTION

FUEL RATE

INTAKE AIR RESTRICTION

INTAKE AIR TEMPERATURE CONTROL - CHASSIS DYNAMOMETER TEST

INTAKE MANIFOLD PRESSURE

LUBRICATING OIL PRESSURE

OPERATION

DYNAMOMETER WORKSHEET

ENGINE DYNAMOMETER - INSTALL ENGINE

AIR COMPRESSOR

AIR INLET RESTRICTION

COOLANT PLUMBING

ENGINE BLOWBY

ENGINE SPEED (RPM) WITH A VERIFIED TACHOMETER

ENGINE THROTTLE CONTROL

EXHAUST RESTRICTION

FUEL DRAIN LINE RESTRICTION

FUEL INLET RESTRICTION

FUEL PRESSURE

FUEL RATE

INTAKE AIR TEMPERATURE CONTROL

INTAKE MANIFOLD PRESSURE

LUBRICATING OIL PRESSURE

LUBRICATING OIL TEMPERATURE

STARTING MOTOR

ENGINE PAINTING

ENGINE RUN-IN PROCEDURE -CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE - ENGINE DYNAMOMETER

ENGINE RUN-IN PROCEDURE - WITHOUT DYNAMOMETER

ON-HIGHWAY

ENGINE STORAGE - LONG TERM

REMOVE THE ENGINE FROM LONG TERM STORAGE

ENGINE STORAGE - SHORT TERM

REMOVE THE ENGINE FROM SHORT TERM STORAGE

ENGINE TESTING - GENERAL INFORMATION

CHASSIS DYNAMOMETER, PORTABLE DYNAMOMETER OR LOAD BANK RUN-IN

DEFINITION OF TERMS ON ENGINE PERFORMANCE CURVE

ENGINE DYNAMOMETER RUN-IN

FUEL FLOW MEASUREMENT ON ENGINE OR CHASSIS DYNAMOMETER

INSTALLATION

OPERATION

GENERAL RUN-IN PROCEDURES

IN-SERVICE RUN-IN

INTAKE MANIFOLD BOOST PRESSURE CORRECTION FACTORS

ENGINE TESTING - SPECIFICATIONS

SERVICE TOOLS - ENGINE TESTING

INSTRUMENTS AND CONTROLS - GROUP 15

INSTRUMENTS AND CONTROLS - GENERAL INFORMATION

AIR HEATERS

COOLANT HEATERS

FUEL WARMERS

GAUGES

OIL HEATERS

SAFETY CONTROLS

MOUNTING ADAPTATIONS - GROUP 16

FLYWHEEL - CLEANING AND INSPECTION FOR REUSE

ASSEMBLY

DISASSEMBLY

INSPECTION

FLYWHEEL HOUSING - CLEANING AND INSPECTION FOR REUSE

CLEANING

INSPECTION

FLYWHEEL RING GEAR - REPLACEMENT

ASSEMBLY

DISASSEMBLY

INSPECTION

FRONT ENGINE SUPPORT - CLEANING AND INSPECTIONS

MOUNTING ADAPTATIONS - EXPLODED VIEW

MOUNTING ADAPTATIONS - GENERAL INFORMATION

REAR ENGINE POWER TAKEOFF - EXPLODED VIEW

REAR ENGINE POWER TAKEOFF (REPTO) REBUILDING

ASSEMBLY

CLEANING

DISASSEMBLY

INSPECTION

SERVICE TOOLS - MOUNTING ADAPTATIONS

SPECIFICATIONS - GROUP 18

CAPSCREW MARKINGS AND TORQUE VALUES

CAPSCREW MARKINGS AND TORQUE VALUES - METRIC

CAPSCREW MARKINGS AND TORQUE VALUES - U.S. CUSTOMARY

COMPONENT SPECIFICATIONS AND TORQUE VALUES

AIR EQUIPMENT - INSPECTION SPECIFICATIONS

AIR INTAKE SYSTEM - INSPECTION SPECIFICATIONS

CAM FOLLOWER ASSEMBLY - REBUILD SPECIFICATIONS

COOLING SYSTEM - REBUILD SPECIFICATIONS

COOLING SYSTEMS - TORQUE VALUES

CYLINDER BLOCK - REBUILD SPECIFICATIONS

CYLINDER BLOCK - TORQUE VALUES

CYLINDER HEAD - REBUILD SPECIFICATIONS

CYLINDER HEAD - TORQUE VALUES

DRIVE UNITS - REBUILD SPECIFICATIONS

ELECTRICAL EQUIPMENT - INSPECTION SPECIFICATIONS

ENGINE ASSEMBLY - CAPSCREW TORQUE VALUES

ENGINE ASSEMBLY - SPECIFICATIONS

ENGINE TESTING - TEST SPECIFICATIONS

EXHAUST SYSTEM - TORQUE VALUES

FUEL PUMP - REBUILD SPECIFICATIONS

FUEL PUMP - TORQUE VALUES

INJECTORS - REBUILD SPECIFICATIONS

LUBRICATING OIL SYSTEMS - SPECIFICATIONS

LUBRICATING OIL SYSTEMS - TORQUE VALUES

MOUNTING ADAPTATIONS - REBUILD SPECIFICATIONS

ROCKER LEVER ASSEMBLY - REBUILD SPECIFICATIONS

VEHICLE BRAKING - REBUILD SPECIFICATIONS

DRIVE BELT TENSION

INJECTIONS TIMING CODES

NEWTON-METER TO FOOT-POUND CONVERSTION CHART

PIPE PLUG TORQUE VALUES

SPECIFICATIONS - GENERAL INFORMATION

TAP-DRILL CHART - U.S. CUSTOMARY & METRIC

WEIGHT AND MEASURES - CONVERSION FACTORS

VEHICLE BRAKING - GROUP 20

VEHICLE BRAKING - GENERAL INFORMATION

SERVICE LITERATURE

ADDITIONAL SERVICE LITERATURE

SERVICE LITERATURE ORDERING LOCATION

COMPONENT MANUFACTURERS: NAMES AND ADDRESSES

COMPONENT MANUFACTURERS' ADDRESSES

AIR COMPRESSORS

AIR CYLINDERS

AIR HEATERS

AIR STARTING MOTORS

ALTERNATORS

AUXILIARY BRAKES

BELTS

CATALYTIC CONVERTERS

CLUTCHES

COOLANT HEATERS

DRIVE PLATES

ELECTRIC STARTING MOTORS

ENGINE PROTECTION CONTROLS

FAN CLUTCHES

FANS

FILTERS

FLEXPLATES

FUEL WARMERS

GAUGES

GOVERNORS

HEAT SLEEVES

HYDRAULIC AND POWER STEERING PUMPS

OIL HEATERS

TORQUE CONVERTERS

INDEX

-