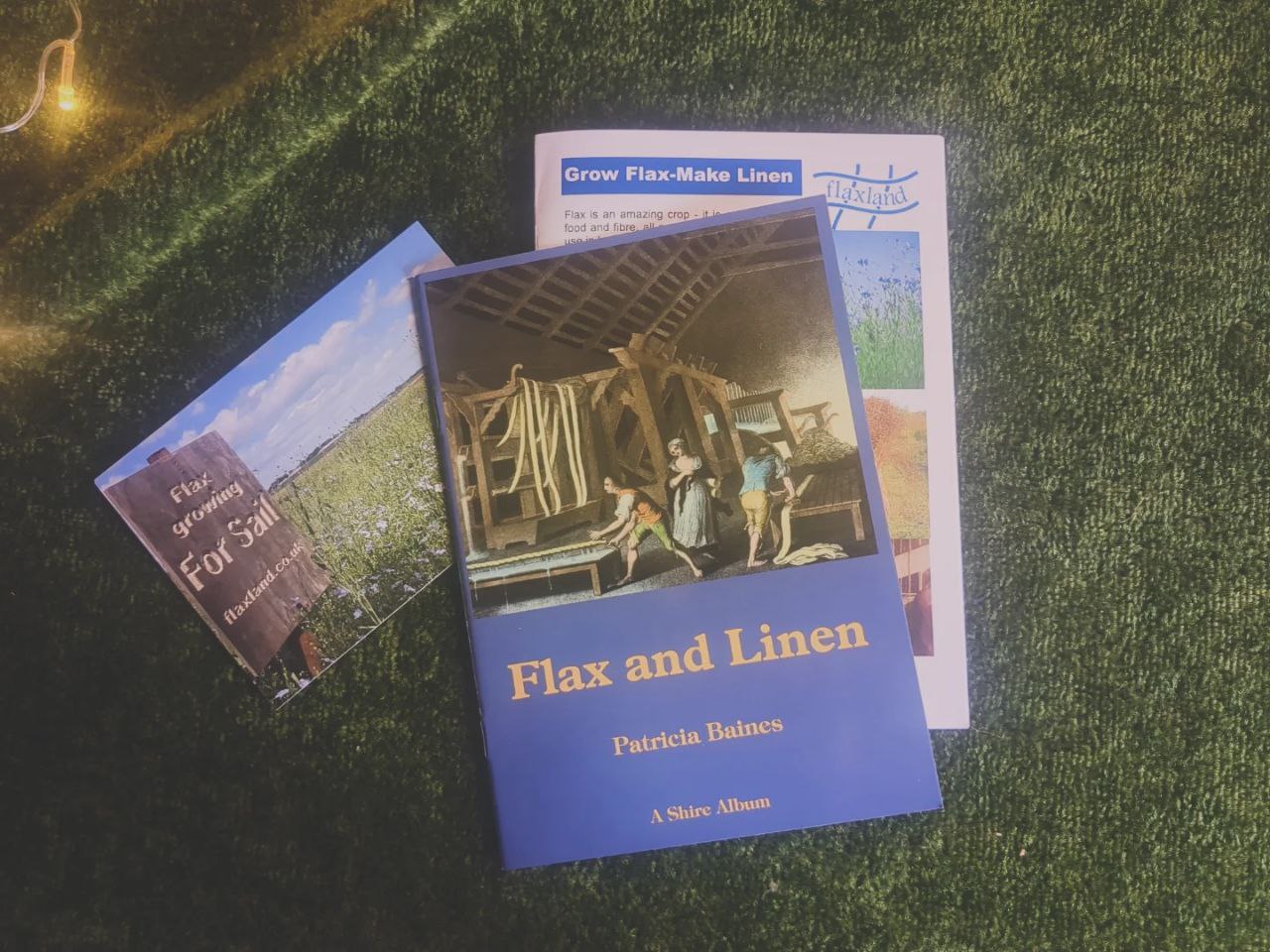

Two booklets are included with the Seed to Cloth kit. The first is Flax and Linen, A Shire Album by Patricia Baines. This describes the flax plant and the various processes involved in turning it into linen cloth with historical photographs and diagrams.

The other booklet contains detailed instructions on how to grow, harvest and process linen at home using the kit.

The kit includes enough flaxseed for 6 square metres of planting, or enough to produce 1000g of fibre, though since the seed and the fibre are harvested at different stages of maturity, some of the fibre harvest will have to be sacrificed to allow the seeds to fully develop so there is seed to plant the following year. Seed should be planted in fine soil in a block, close together so that the stems grow straight and tall.

The instructions advise mixing the seeds with sand, soil, or sawdust to allow them to be broadcast more evenly over the planting area. They should be planted from mid April to the end of May, then raked in to a depth of 25mm before the soil is firmed with the back of a rake.

The seeds are expected to germinate within 2 weeks and the young plants monitored for signs of flea beetle damage (which a quick search on the internet tells me can be recognised as small pale spots eaten into the leaves, and can be prevented from damaging seedlings by covering with an insect-proof mesh as soon as possible after planting).

The plants flower in late June to early July, with attractive blue flowers that each last for less than a day. They can be harvested around mid August, once the round seed bolls have turned brown, and are pulled up by the root to preserve the full length of the fibre. At this stage, the stems are often still green so the plants are left to dry in the sun for 2 weeks to allow them to finish ripening, after which they are rippled to remove the seeds for planting in the next year.

Rippling is done by pulling the plants through a large comb that pulls off the seed heads, or by scraping them off between two pieces of wood. The seed bolls can then be beaten or thrashed to break them open, then the seeds sieved and cleaned.

Once the seeds have been removed, the stems are retted, which is a process of partial decomposition that can be done in fresh water (though this is smelly and polluting), by specialised chemicals at the industrial level, or by dew or field retting, in which the natural moisture from dew and rain and the weathering effects of the wind and sun break down the stems to release the fibres. To dew ret, the stems should be spread out on the ground with all the root ends together in a mat 25mm to 50mm deep.

The stems need to be turned weekly, and are estimated to take between 4 and 6 weeks, though this seems to depend heavily on the weather. The good news is that it can be partially retted, brought in and dried, and the retting process restarted later. Dried flax can also be stored for a long time, so the timescale for this can be pretty relaxed as long as it's not left out too long.

Once the fibres come away easily from the shives (the woody part of the stalk) and don't stick together, the flax needs to be dried completely before it is processed. The instructions say it's best to wait at least 8 weeks for the easiest processing.

The kit contains samples of both unprocessed flax straw and some flax fibres ready to spin, so we don't have to wait a year to grow our own flax.

The next stages are breaking, scutching, and hackling, all of which should be done wearing a mask and gloves (and probably eye protection as well), as the processing is dusty and the straw is brittle and can be sharp enough to cause splinters.

Breaking involves crushing the stems to break off the bark. This would originally have been done in a flax break, which was a device with wooden blades that would be applied in a chopping motion. The kit provides instructions for crimping and crushing by holding the straw between the processing tool and a wooden board and lifting the stems 90 degrees, then moving the block along by 1cm and repeating, starting from the roots and working towards the tops of the stems.

This is followed by scutching, shaking off any loose bark and working the straw between your hands to release more, then stroke (scutch) the fibres along their length from middle to end with the flat edge of the processing tool. Repeat from the middle to the other end.

Finally, hackling uses the toothed edge of the wooden processing tool to comb from the centre past the ends of the straw to remove tangles and shives. Once most of the shives are removed, hackling is repeated using a metal comb.

This results in three products: shives, which are the wood and bark waste products; tow, which are the short, coarse fibres combed out during hackling; and line, which is the longer and finer linen fibre.

Tow can be used to produce coarser products such as garden twine, while the line is used for finer threads.

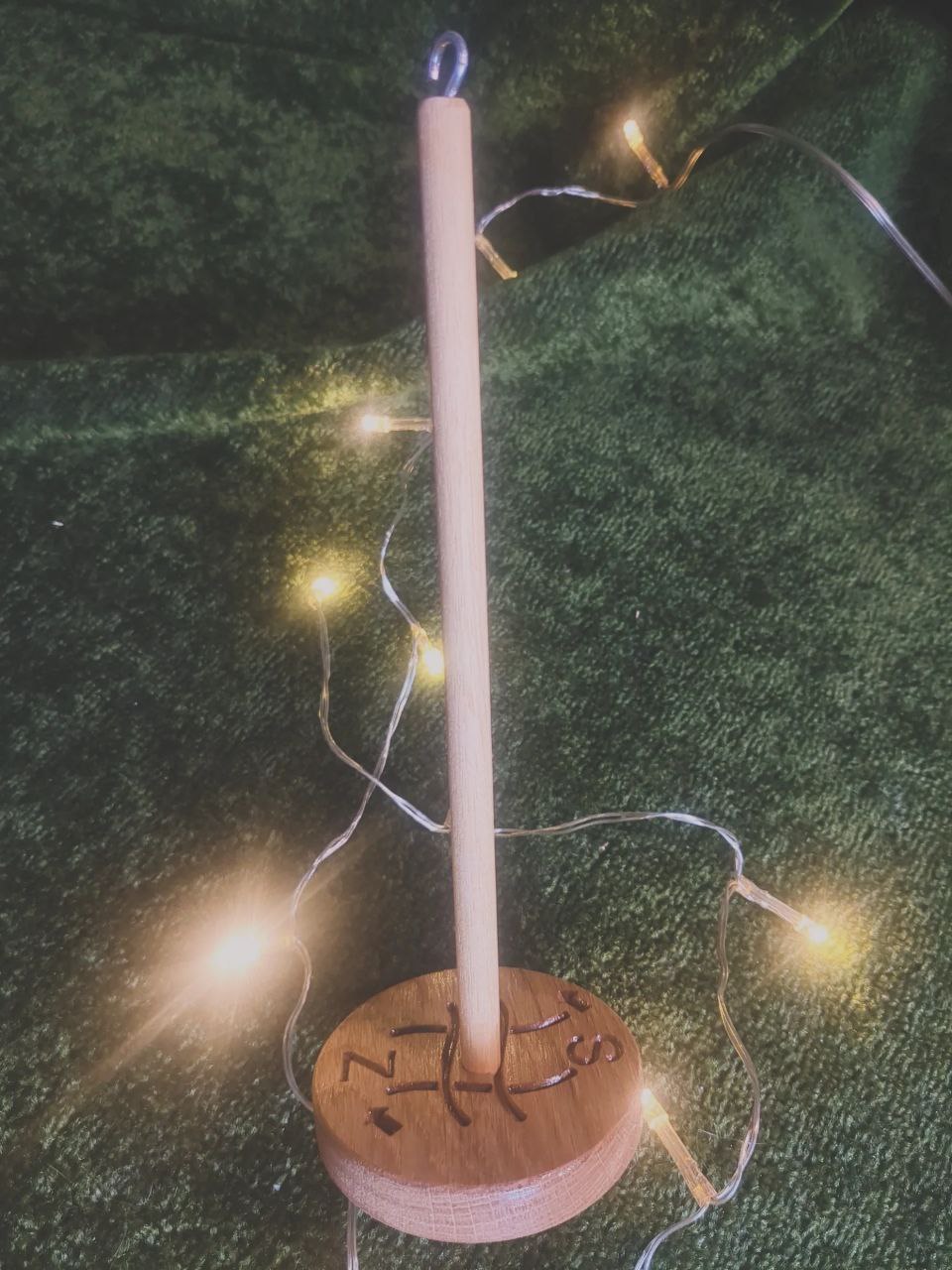

The line is then spun using a spinning wheel or drop spindle, but the process is a little different to the spinning of wool. A distaff is a rod with a cone or lantern shaped removable top around which the flax fibres are wound, called dressing, to hold them while they are being spun. The kit contains instructions on how to make a distaff using household objects, and how to dress the distaff using the processed flax fibre provided.

The provided ribbons are used to secure the fibre to the distaff, which leaves both hands free to draft the fibres and control the spindle. Unlike wool, flax fibres are usually spun wet by dipping your fingers in a bowl of warm water. This adds twist and smooths the fibres for a finer result.

Plying involves twisting two threads together to make one stronger thread, and is also performed using the spindle or spinning wheel.

Finally, the flax thread is woven into linen fabric on a loom.

Fine tow that can be carded can be spun in the same way as wool. The kit also includes a twine winder for spinning coarser tow. This is a two person operation - one person holds the hooked implement and cranks the handle, the other draws out the fibres.

So that's the kit, and rather an in-depth read despite the small size of the booklets. I'm really looking forward to giving these activities a try, probably starting with constructing a distaff for myself so I can attempt to dress it and start spinning.

Comments ()